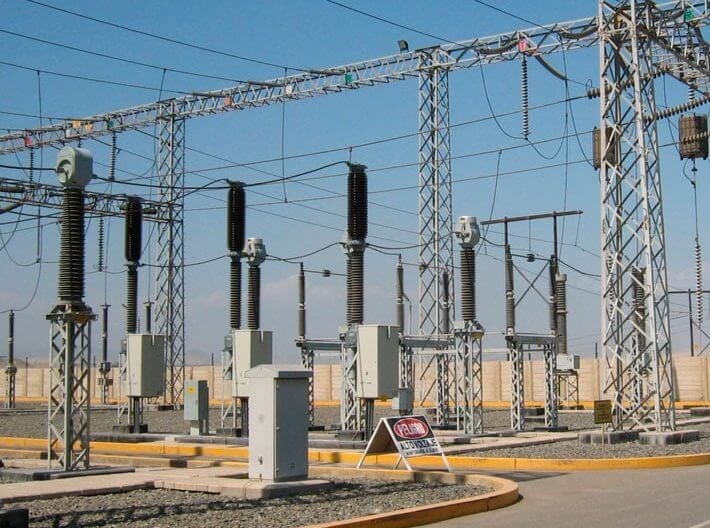

Substation automation is the key to the modern evolution of power systems. This crucial process changes the way the electrical infrastructure is run and monitored. The specifics of automated substation technologies are an added advantage to professionals who have been working with power systems for a long time. They are also essential for remaining competitive and performing well in operations.

This change in how power systems operate (manual control to automated intelligent systems) has revolutionized how power systems are operated as far as reliability, efficiency and safety are concerned in the industry. Contemporary substation automation includes complex control algorithms, real-time data processing and control protocols that have never been seen before, which allow a high degree of grid intelligence and responsiveness.

Power systems that are found in the modern world are faced with more complex challenges like the integration of the renewable energy sources, variations in loads, cybersecurity threat, and the need to comply with regulations. The problems demand automation capabilities far beyond simple remote control capabilities that would introduce a full system intelligence, predictive analytic and autonomous decision making capabilities in order to enhance overall grid performance.

The Evolution of Modern Substation Automation Systems

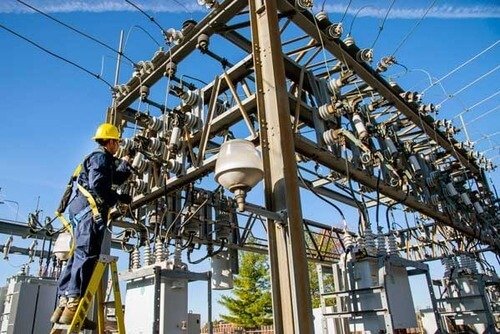

The journey from electromechanical control systems to today’s digital substation automation system implementations reflects decades of technological advancement and operational experience. Initial automation went towards remote monitoring and simple control tasks but now incorporate numerous layers of intelligence and turn substations into active nodes of grid control.

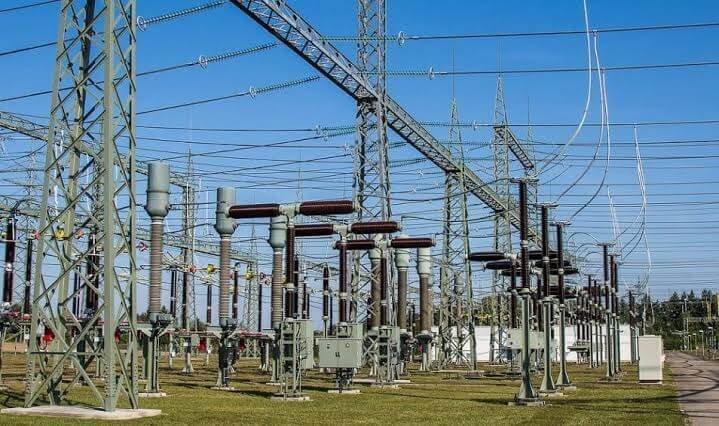

Digital transformation has allowed substations to become active hubs of a network that actively cooperate in grid optimization. Advanced algorithms are continuously used to analyze the conditions of the system, to predict the behavior of equipment and take corrective measures to ensure that the system performs optimally and safeguard the critical infrastructure.

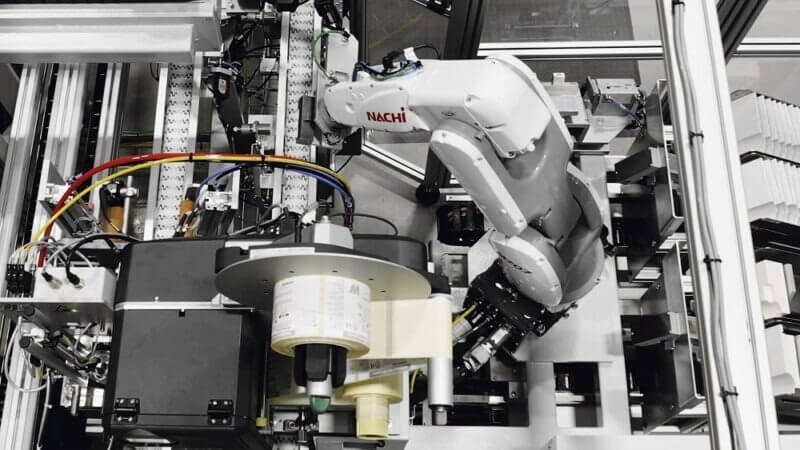

Artificial intelligence and machine learning technologies are the latest trend in the automation development. These powerful abilities allow the substations to receive insights based on the patterns in the operation, detect a developing problem before it becomes a serious one, and maximize the work on the basis of the past and future trends.

Moreover, interoperability of systems by different manufacturers has never been possible due to the standardization of communication protocols especially IEC 61850. This standardization allows utilities to adopt best-of-breed solutions without compromising system integration and minimizing long-term maintenance complexities.

Core Technologies Driving Automation Excellence

Intelligent Electronic Devices and Control Systems

Modern substation automation products center around sophisticated intelligent electronic devices (IEDs) that combine multiple functions into integrated platforms. These devices perform protection, monitoring, control, and communication functions while providing the computational power necessary for advanced analytical capabilities.

Microprocessor-based protection relays form the foundation of most automation architectures. These devices not only provide primary and backup protection functions but also serve as data acquisition points, local controllers, and communication gateways that enable system-wide coordination and optimization.

Advanced control systems integrate multiple IEDs into cohesive automation platforms that can execute complex control sequences, manage load transfers, and coordinate with external systems. These control platforms provide the intelligence necessary for autonomous operation while maintaining human oversight capabilities.

The evolution toward software-defined control systems enables greater flexibility and functionality compared to traditional hardware-based approaches. Software-defined platforms can be updated and enhanced throughout their operational life, providing long-term value and adaptability to changing requirements.

Communication Infrastructure and Networking

Robust communication infrastructure represents the nervous system of modern automation implementations. High-speed networks enable real-time data exchange between devices, systems, and remote control centers while supporting the bandwidth requirements of modern digital substations.

Fiber optic communication networks provide the reliability and performance necessary for mission-critical applications. These networks support multiple communication protocols simultaneously while providing the security and electromagnetic immunity essential for substation environments.

Wireless communication technologies offer additional flexibility for specific applications including temporary installations, mobile substations, and locations where fiber installation is challenging. Advanced wireless systems provide security and reliability comparable to wired solutions while offering deployment advantages.

Network redundancy and failover capabilities ensure continuous operation even during communication system failures. Multiple communication paths and automatic switching mechanisms maintain system functionality while providing transparent recovery from network disruptions.

Advanced Substation Automation Solutions and Applications

Protection System Integration

Protection schemes in modern systems are well incorporated into automation platforms to ensure better security and reliability of the system. Fine protection algorithms have the ability to study the conditions of a system on a wide-range of substations so that wider-area protection schemes have been implemented that are able to detect and clear faults more efficiently than conventional methods.

Adaptive protection features do not require any human intervention to change protection settings, which changes depending on the real-time system conditions. Such systems are able to alter protection properties during the maintenance processes, abnormal operating conditions, or emergencies to assure the best protection coverage and accommodate operational flexibility.

With synchrophasor technology integration, real-time observation of system dynamics on wide geographic scales is possible. This brings new levels of visibility to power system behavior and enables more sophisticated applications such as stability monitoring, oscillation detection, and controlled islanding strategies.

Digital fault recording and event analysis functions give precise data on the interferences in the system that can be applied to enhance protection settings, detect problems of equipment and improve the entire system performance. Such analytical capabilities shift fault investigation into a proactive system optimization process.

SCADA Integration and Remote Operations

Supervisory control and data acquisition (SCADA) integration enables centralized monitoring and control of multiple substations from remote control centers. Modern SCADA systems provide comprehensive situational awareness while supporting operator decision-making through advanced visualization and analytical tools.

Real-time data processing capabilities enable control center operators to monitor thousands of data points continuously while receiving automatic alerts for abnormal conditions. Advanced alarm processing and prioritization systems help operators focus on critical issues while filtering routine operational notifications.

Remote control capabilities allow operators to perform switching operations, adjust equipment settings, and respond to emergency conditions from centralized locations. These capabilities reduce response times while enabling more efficient use of skilled personnel across multiple facilities.

Historical data analysis and reporting functions provide insights into long-term trends, equipment performance, and system optimization opportunities. These analytical capabilities support asset management decisions, maintenance planning, and operational improvements that enhance overall system performance.

Energy Management and Optimization

Advanced energy management functions optimize substation operations to reduce losses, improve power quality, and enhance overall system efficiency. These functions continuously monitor system conditions and implement control actions that maintain optimal performance across varying load conditions.

Demand response integration enables substations to participate in grid-wide optimization programs that balance supply and demand while reducing overall system costs. Automated demand response capabilities can shed non-critical loads during peak demand periods while maintaining essential services.

Power quality monitoring and correction systems automatically detect and mitigate power quality disturbances that can affect sensitive industrial and commercial loads. These systems protect customer equipment while maintaining voltage and frequency within acceptable limits.

Load forecasting algorithms predict future demand patterns and optimize equipment operations accordingly. These predictive capabilities enable proactive resource allocation and help prevent overload conditions that could compromise system reliability.

Implementation Strategies for Substation Automation

System Architecture and Design Considerations

Successful automation implementations require comprehensive system architecture planning that addresses current needs while providing flexibility for future expansion. The architecture must balance performance requirements with cost considerations while ensuring long-term maintainability and obsolescence management.

Scalable design approaches enable incremental implementation that spreads costs over multiple budget cycles while providing immediate operational benefits. Modular architectures allow utilities to implement automation capabilities in phases based on priority and available resources.

Cybersecurity considerations must be integrated into the architecture from the initial design phase. Modern automation systems require comprehensive security measures including network segmentation, access control, encryption, and continuous monitoring to protect against evolving cyber threats.

Standards compliance ensures interoperability and reduces long-term maintenance costs. Adherence to international standards including IEC 61850, IEEE standards, and regional requirements provides confidence in system performance and enables multi-vendor implementations.

Integration with Legacy Systems

Most automation projects must integrate with existing legacy equipment and systems that may have been installed over several decades. Successful integration requires careful analysis of existing systems and development of migration strategies that minimize operational disruption.

Protocol conversion and gateway technologies enable communication between modern automation systems and legacy equipment. These technologies extend the useful life of existing investments while providing migration paths toward full automation implementation.

Phased implementation approaches allow utilities to modernize substations incrementally while maintaining operational continuity. These approaches minimize project risks while providing immediate benefits from each implementation phase.

Training and change management programs ensure that operational personnel can effectively utilize new automation capabilities. Comprehensive training programs address both technical system operation and new operational procedures that automation enables.

Partnership Strategies and Vendor Selection

Working with Substation Automation Channel Partners

Successful automation projects often depend on effective partnerships with experienced substation automation channel partners who bring specialized expertise and implementation experience. These partnerships provide access to technical knowledge, project management capabilities, and ongoing support services that enhance project success.

Channel partners offer valuable insights into technology trends, best practices, and lessons learned from similar implementations. Their experience with multiple projects and diverse applications provides perspective that can improve design decisions and avoid common implementation pitfalls.

Local partnership arrangements provide advantages including regional knowledge, faster response times, and better understanding of local regulations and requirements. These partnerships are particularly valuable for utilities operating in multiple geographic regions with varying technical and regulatory requirements.

Long-term support capabilities represent critical considerations when selecting channel partners. Automation systems require ongoing maintenance, updates, and technical support throughout their operational life, making partner capabilities and stability important selection criteria.

Technology Selection and Procurement

Technology selection requires careful evaluation of multiple factors. This include technical performance, lifecycle costs, vendor stability, and support capabilities. Comprehensive evaluation processes help ensure that selected technologies will meet both current requirements and future needs.

Total cost of ownership analysis must consider the initial procurement costs and other costs. These include installation, training, maintenance, and replacement costs. This comprehensive financial analysis provides an accurate basis for technology comparison and selection decisions.

Performance specifications should address functional and non-functional requirements. This include reliability, availability, maintainability, and security. Clear specifications help ensure that procured systems will meet operational needs and performance expectations.

Vendor qualification processes evaluate manufacturer capabilities, financial stability, technical support capabilities, and track record with similar implementations. These evaluations help identify vendors who can provide reliable long-term partnerships rather than simply competitive pricing.

Conclusion

Substation automation is taking over our industry with the evolution of technology, operational needs, and evolving grid characteristics. Automation technologies can be rather demanding to implement, and the implementation can be successful when making sure that the available solutions are clearly comprehended, a well-developed plan is available, and joint ventures are strategic to reach long-term success.

The knowledge base of modern automation systems is wide and general in technical areas as well as specialized and oriented towards reliability of operation and safety. The companies that will invest in the entire automation strategies will be in a position to experience the benefits of improved operational efficiency and reliability and reduced cost in the long run.

In the current power systems management environment, the organizations that want to become the best have to associate with well-established firms in the industry to provide the expertise and stability needed in the implementation of automation. 75 years of excellence in electrical engineering in East Africa means that IET is well placed to offer end-to-end substation automation systems that transform performance. Our experience and expertise in the region and our ability to partner with the world-leading automation technology providers will guarantee that your investments in critical infrastructures perform optimally and are reliable. Reach out to our automation experts now to find out how our track record in power transmission and distribution and intelligent control systems can help get your next-generation substation automation to a new level of performance.