The world today requires complex management strategies in modern buildings during the course of their functioning. In such a complicated infrastructure, structural solutions are needed in a complex system that covers all the stages. Effective oversight is identified as the determining success of operations in the initial design to decommissioning. Companies delivering advanced solutions for building lifecycle management play a crucial role in this ecosystem.

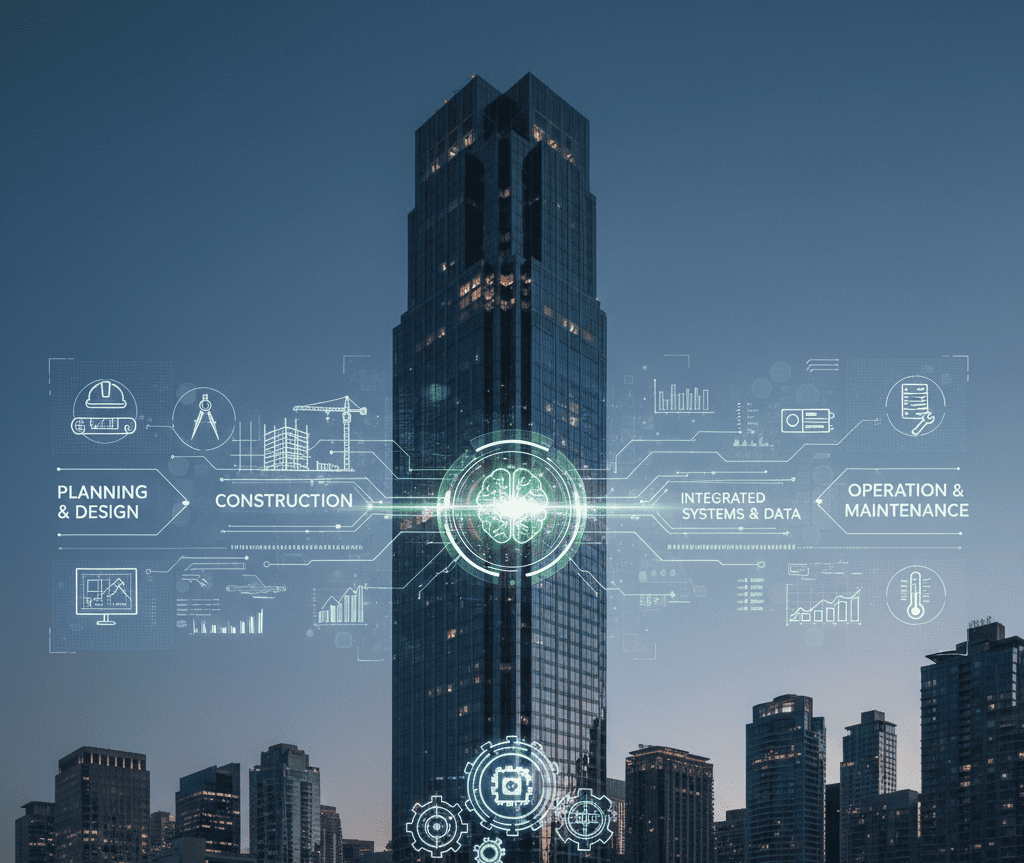

The lifecycle management construction involves building planning, design, construction, operation, and maintenance. With every stage, there comes with challenges of its own which demand specialized knowledge. The appropriate technology partners will help organizations to maximize the performance in the different stages. Data and systems integration provide smooth working processes.

The pre-selection of the technology partners should be done carefully by evaluating various factors. Organizations have to take into account technical abilities and one should take into account industry experience and the long-term support infrastructure. This article explores critical considerations when choosing companies delivering advanced solutions for building lifecycle management. We will look at some of the important competencies, technological breakthroughs, and strategic strengths that distinguish industry leaders.

Development of the lifecycle management is a comprehensive strategy in facilities management and optimization. It incorporates both the physical assets and the digital systems and the processes into singular structures. The methodology allows to maximize value generation out of infrastructure investments. When done correctly, it lowers the operation costs and the lifespan of the assets is increased tremendously.

Understanding Building Lifecycle Management Fundamentals

The lifecycle starts with the planning and viability studies at the conception phases of the lifecycle. The design and the engineering team work together to develop technical specifications and performance requirements. The construction phases lead to transfer of plans to physical reality with coordinated efforts on implementation. It is through commissioning that all systems are validated to be operating as specified.

The most resource-intensive and the longest part of the lifecycle is operational phases. This long period is filled with repairs and modifications as well as ongoing optimization. Companies delivering advanced solutions for building lifecycle management provide tools for predictive maintenance. The capabilities reduce downtime and avoid expensive emergency repair.

End-of-life considerations include decommissioning, demolition, or repurposing strategies for existing structures. Environmental impact assessments guide sustainable disposal or renovation approaches. Forward-thinking organizations plan for these eventualities from project inception. Circular economy principles increasingly influence terminal phase decision-making processes.

Core Technologies in Modern Building Management

Integrated Building Management Systems

BMS are the brain of the current-day facilities. Such platforms oversee and manage HVAC, lighting, security, and power networks. The ability to make informed decisions and swift response to them is achieved through the use of real-time data collection. Advanced building management solutions limited to basic functions no longer meet contemporary demands.

Artificial intelligence and machine learning build predictive analytics into modern systems. Energy consumption patterns indicate potential optimizations to reduce operational costs. Computer-controlled reactions to environmental changes ensure the maintenance of the best environmental parameters. Its integration with IoT devices exponentially enhances the system’s ability to monitor.

Scalability is one such issue that is paramount in estimating building management platforms. We should design the systems to support facility expansions and technological upgrades without requiring an entire replacement. We can enhance budgets incrementally by using modular structures. Traditional on-premise systems can not be flexible as cloud based solutions do.

Power Quality and Distribution Management

The electrical infrastructure is the base of all operations and functionality of buildings. The quality of power will directly affect the benefits of equipment life, efficiency in operations, and system reliability. Harmonic distortions and voltage variations lead to untimely and unforeseen failures. Companies delivering advanced solutions for building lifecycle management prioritize power quality optimization.

Mature switchgear and transformer systems provide constant supply of power to the whole facility. The switchboards of medium voltage and low voltage need the exact engineering to be able to perform optimally. Smart monitoring will be able to identify abnormalities before they transform into severe failures. The solutions of power factor correction reduce the utility costs significantly and waste.

Variable frequency drives offer very accurate motor control as well as minimizing the amount of energy used. With these technologies, soft starts can be conducted which will remove mechanical stress on the equipment. Regenerative facilities recenter energy into systems when deceleration occurs. Motor control centres achieve integration by issuing protection, control and monitoring as one.

Automation and Control Systems

Industrial automation transforms manual processes into efficient, repeatable, and accurate operations. Programmable logic controllers orchestrate complex sequences with millisecond precision. Human-machine interfaces provide intuitive control and visualization of operational parameters. Companies delivering advanced solutions for building lifecycle management leverage automation extensively.

SCADA systems offer supervisory control and data acquisition across distributed facilities. Remote monitoring capabilities enable centralized management of geographically dispersed assets. Historical data archives support trend analysis and continuous improvement initiatives. Real-time alerts notify personnel of deviations requiring immediate attention.

Automation construction goes outside industry to commercial and residential uses. Smart lighting systems can change the brightness depending on the occupancy and the availability of natural lighting. Climate control systems afford comfort and save on the consumption of energy by means of zoning. The security systems and access control systems are compatible with other functions of the building.

Strategic Considerations for Partner Selection

Technical Expertise and Industry Experience

Organizations should prioritize companies delivering advanced solutions for building lifecycle management with proven track records. The years of operating experience suggest the perfected methodologies and the knowledge gained. Expert knowledge in the industry provides knowledge of the peculiarities of challenges and the rules. Case studies and references of clients give information about good insights on levels of capability.

Training programs pass on knowledge to the internal teams and generate the development of operational self-sufficiency. In-depth documentation is necessary so as to have organizations familiar with the system architectures and functions. The products of the advanced building management solutions ltd must involve effective educative features. Transfer of knowledge lessens the dependence of the external support sources over a period of time.

Technological Innovation and Future-Readiness

The fast rate of technological change requires partners who are focused on an ongoing process of innovation. Backward compatibility safeguards the current investments as well as providing some ability to follow progressive modernization schemes. The Open architecture systems make it easier to integrate with new technologies and new standards. Proprietary solutions establish vendor lock-in which limits flexibility in the future.

The attention to cybersecurity becomes ever more significant as systems are becoming more interdependent and opened. Firm security measures are in place against access by unauthorized persons and malicious intent. The vulnerabilities and the threat vectors discovered frequently are addressed with regular updates. Companies delivering advanced solutions for building lifecycle management must prioritize security throughout design processes.

Energy efficiency innovations respond to environmental concerns and operational cost pressures. Renewable energy integration capabilities prepare facilities for sustainable power sources. Energy storage systems buffer supply fluctuations and reduce peak demand charges. Smart grid connectivity enables participation in demand response programs.

Comprehensive Service and Support Infrastructure

Post-installation support determines long-term satisfaction and operational success with building management systems. Responsive technical support minimizes downtime during unexpected issues or system failures. Preventive maintenance programs identify potential problems before they impact operations. Companies delivering advanced solutions for building lifecycle management invest heavily in support infrastructure.

Geographic proximity affects response times and service quality for physical interventions. Local presence demonstrates commitment to regional markets and client relationships. Parts availability ensures rapid repairs without extended downtime waiting for components. Workshop facilities enable testing, repairs, and custom fabrication when required.

Lifecycle management encompasses financial planning and budgeting assistance, and it does not limit itself only to technology. TCO analyses can inform investment decisions and prioritization activities. Performance ensures that the vendors’ interests align with client operational goals. Flexible financing arrangements accommodate the different budgetary constraints and cash flows.

Evaluating Solutions for Different Building Types

Commercial and Office Buildings

Commercial buildings are focused on occupant comfort, energy conscientiousness, and minimization of cost of operation. Zonal climate control meets the different thermal preference of different spaces. The lighting systems combine the effectiveness of energy efficiency and sufficient lighting to the workplaces. Apart, the best solutions when dealing with small residential constructions and those used in commercial stands are very different.

The access control systems regulate the security and provide an easy entry of authorized staff. Monitoring of the elevators and predictive maintenance avert inconveniences to vertical transportation systems. Automation management in conference rooms eases the usage of technology, and productivity of meetings. Companies delivering advanced solutions for building lifecycle management tailor offerings to commercial contexts.

Energy management systems automate the consumption trends and the areas of optimization of operations. Occupancy sensors regulate systems based on the real use of the spaces and not on schedules. The demand response would help in minimizing the cost during high pricing times. Sustainability reporting shows the environmental stewardship to stakeholders and the regulatory agencies.

Industrial and Manufacturing Facilities

The industrial setting requires powerful systems that can withstand the hostile operation factors. Automation of the processes guarantees quality production and maximum output. Maintenance predicts equipment maintenance and avoids unexpected downtimes. Companies delivering advanced solutions for building lifecycle management understand industrial-specific requirements.

The equipment’s sensitivity in the manufacturing environment makes the quality of power even more vital and challenging. Harmonic filtering defeats power quality noise in sensitive electronics. UPS systems keep most essential processes going when the utility fails. Back-up systems provide security for work-in-progress or manage unplanned interruptions.

Material handling systems integrate with building automation for optimized workflow coordination. Environmental monitoring maintains required conditions for product integrity and worker safety. Compliance tracking documents adherence to regulatory standards and industry best practices. Production analytics inform continuous improvement initiatives and capacity planning decisions.

Healthcare and Critical Infrastructure

Healthcare facilities require exceptional reliability given the life-safety implications of system failures. Redundant systems ensure continuous operation even during maintenance or component failures. Emergency power systems activate instantaneously during utility interruptions to sustain critical functions. Companies delivering advanced solutions for building lifecycle management recognize these heightened requirements.

Environmental controls maintain strict temperature and humidity parameters in sensitive areas. Air quality management prevents contamination and maintains sterile environments where required. Patient monitoring integration connects medical systems with building management platforms. Alarm management prioritizes critical alerts while preventing alarm fatigue among staff.

Implementation Best Practices and Risk Mitigation

Planning and Requirements Definition

Thorough planning and congruency between stakeholders in purpose initiate effective implementations. Requirements gathering entails the functional requirements, performance requirements and constraints parameters. Specifications are in detail, which helps also with the choice of vendors and avoids confusion until the execution stages. Companies delivering advanced solutions for building lifecycle management facilitate these critical planning processes.

Incremental learning during projects is also possible because of possibility of phased approaches, which minimize risks in implementation. Pilot programs prove ideas prior to large scale implementations on entire facilities. Change management strategies equip the organization with operational transition and new workflow. The training plans will make the personnel acquire the required competencies prior to the activation of the system.

There is budget development covering overall implementation costs: hardware, software and services. Contingency reserves help in solving unexpected difficulties that arise at the stages of implementation. Financing arrangements match payment payments with the milestones and acceptance of deliverables of the project. Value engineering determines the opportunities of cost optimization that do not affect help in the functional requirement.

Testing, Commissioning, and Validation

Companies delivering advanced solutions for building lifecycle management employ systematic testing protocols. They perform strict testing to ensure that the systems installed meet the required performance standards before they accept them. These companies conduct a factory acceptance test to ensure the machines are working when they ship them to the project sites. They use the site acceptance test to ensure that they install and interconnect everything with the existing infrastructure.

Processes of commissioning record the performance on the basis and form guideline on future operational levels. Load testing confirms capacity as well as indicating performance constraints during peak times. Failure mode testing ensures that redundant systems come online when the emergency is simulated. Performance optimization optimizes configurations to achieve optimal efficiency and effectiveness.

Documentation packages transfer knowledge and provide reference materials for operational teams. As-built drawings reflect actual installations rather than original design intentions. Operation and maintenance manuals guide routine procedures and troubleshooting efforts. Training materials support ongoing skill development and new employee orientation programs.

Measuring Success and Continuous Improvement

Key Performance Indicators and Metrics

Effective lifecycle management requires defined metrics that quantify performance against established objectives. Energy consumption per square meter benchmarks efficiency and identifies improvement opportunities. Equipment uptime percentages measure reliability and maintenance program effectiveness. Companies delivering advanced solutions for building lifecycle management help define meaningful metrics.

Maintenance cost ratios compare preventive versus corrective expenditures to assess program balance. Mean time between failures indicates equipment reliability and optimal replacement timing. Response time metrics evaluate support team effectiveness during operational incidents. User satisfaction surveys capture qualitative perspectives on system performance and functionality.

Financial performance measures the technology implementation payment payback and returns. Lifecycle budgeting and replacement planning are made informed by total cost of ownership calculation. Energy cost avoidance measures effectiveness missions and demand control. Sustainability metrics record that there are environmental impacts reduction and corporate goal advancement.

Optimization and Evolution Strategies

Constant improvement techniques utilize operational data to add to incremental improvement activities in the long term. The trend analysis exposes the deteriorating performance prior to failures and gives a chance to intervene before it happens. The comparisons with industry standards made by benchmarking the performance determine the gaps and the areas of improvement. Companies delivering advanced solutions for building lifecycle management support ongoing optimization efforts.

Technology refresh cycles provide equilibrium between innovation adoption and budget limits and minimization of disruptions. Modular upgrade paths permit the selective enhancement of the high-impact sub systems but not upgrades of the whole subsystems. The conditions of backward compatibility offer to maintain pre-existing investments without compromising them and provide the possibility to introduce improvements. Migration plans facilitate the review of old systems to new systems.

The use of stakeholder feedback loops captures the user experiences in the system and directs previous areas to improve first. It takes place during the operational reviews to determine whether the objectives have been attained, and corrective actions are taken where necessary. The work of sharing best practices between the facilities promotes speedy acquisition of knowledge and eliminates the existence of similar issues that are addressed in different workplaces. External audits give objective research and substantiation to internal claims of performance.

Conclusion

Choosing the appropriate technology partners has far-reaching implications on the establishment of operational success over lifetimes. The aspects discussed in this paper can inform organizations to make sound decisions when entering into partnerships. Companies delivering advanced solutions for building lifecycle management bring expertise that transforms infrastructure investments. Long-term satisfaction and value realization is defined by technological sophistication, established experience and overall supporting support.

IET is a company that has more than 75 years of excellence in electrical engineering in East Africa in the provision of building lifecycle management solutions. With our expertise we have covered power distribution, automation of building construction, industrial controls and energy management systems. We have global technology alliances and local presence and knowledge of local needs. Contact IET today and find out how our integrated solutions would streamline the operation of your facility and help you pull the most out of the investment in your infrastructure.