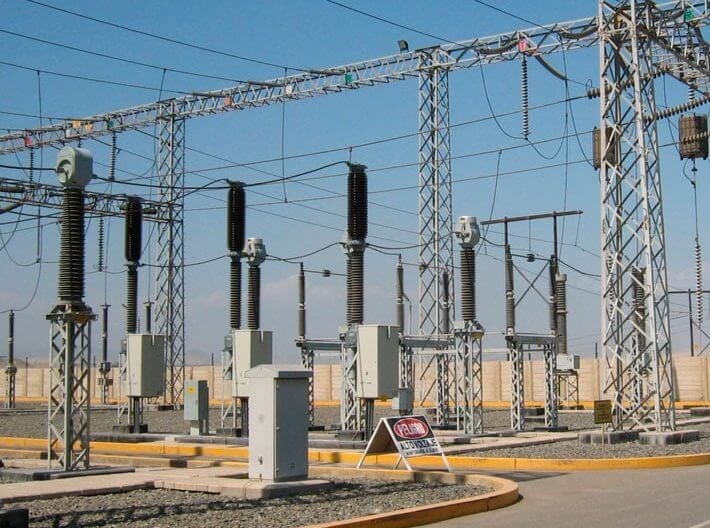

Electric substations are the core of electrical transmission and distribution systems. These stations ensure a safe and efficient delivery of electricity to generations sources and end consumers—businesses and domestic use. For an electric power substation to perform and ensure system reliability, operational efficiency, and long-term infrastructure sustainability, it’s important to understand what each of the electric substation components does. These smart installations are where a lot of inter-related components come together to work towards ensuring power quality and system stability.

The practicality of the contemporary electric grids requires deep understanding of the operation of the different electrical substation components both independently and together. Whether it is huge power transformers or the complex protection relay systems, all these components are extremely important to ensure smooth functioning of the electrical network. The mentioned technical landscape is ever-changing due to the increasing technology, and professionals must be up to date about the most recent changes in the electrical substation equipment.

Primary Power Transformation Equipment

Power Transformers: The Heart of Substations

Power transformers in substations represent the most critical and expensive components in any electrical substation. These electromagnetic devices facilitate voltage level changes necessary for efficient power transmission and distribution. The selection and specification of appropriate transformer configurations directly impact system performance, efficiency, and reliability.

Substation power transformers come in various configurations, including single-phase and three-phase units, with power ratings ranging from a few MVA to several hundred MVA. The choice between different transformer types depends on factors such as system voltage levels, load requirements, fault current capabilities, and environmental considerations.

Key considerations for substation transformers include:

- Voltage regulation capabilities under varying load conditions

- Impedance characteristics for fault current limitation

- Cooling system requirements and efficiency

- Insulation coordination with system voltage levels

- Environmental protection and containment systems

Transformer Auxiliary Systems

Substation transformer parts extend beyond the core electromagnetic components to include essential auxiliary systems. These supporting elements ensure optimal transformer performance and longevity. Cooling systems, whether natural air, forced air, or oil circulation, maintain operating temperatures within acceptable limits.

Bushings provide insulated connections between transformer windings and external circuits. These critical components must withstand both electrical and mechanical stresses while maintaining insulation integrity. Tap changers, whether on-load or off-load types, enable voltage regulation to accommodate varying system conditions.

Switching and Protection Equipment

High Voltage Switchgear

The main switching devices in electrical substations are circuit breakers which offer the capability to interrupt fault currents and de-energize equipment to perform maintenance. Contemporary circuit breakers technology encompasses SF6 gas-insulated breakers, vacuum interrupters and air-blast circuit breakers with each having its own applicative benefits.

The disconnect switches make the equipment and circuits visibly isolated, which keeps the personnel safe during maintenance procedures. Such devices are normally used at no-load conditions but the device is to be capable of full system voltage and current ratings.

Load break switches are a combination of disconnect switches with limited current interrupting capacity, to provide flexibility in operation of the system to reconfigure and manage loads.

Protection and Control Systems

Protective relay systems monitor electrical parameters and initiate appropriate responses to abnormal conditions. Modern digital relays offer sophisticated protection algorithms, communication capabilities, and extensive data logging functions. These intelligent devices can detect various fault conditions including overcurrent, differential, distance, and frequency anomalies.

Current transformers (CTs) and voltage transformers (VTs) provide scaled representations of primary system quantities for measurement and protection purposes. Accurate ratio transformation and burden characteristics are essential for proper relay operation and system monitoring.

Power Quality and Conditioning Equipment

Reactive Power Compensation

Capacitor banks provide reactive power support to improve system power factor and voltage regulation. These installations can be fixed or automatically switched based on system requirements. Proper sizing and switching logic are critical for optimal system performance.

Reactors, both shunt and series types, provide inductive reactance for various system applications. Shunt reactors compensate for capacitive charging currents in long transmission lines, while series reactors limit fault currents and provide voltage regulation.

Voltage Regulation Equipment

Static VAR compensators (SVCs) and static synchronous compensators (STATCOMs) provide dynamic reactive power control for voltage stability and power quality improvement. These devices respond rapidly to system changes, maintaining voltage levels within acceptable limits.

Voltage regulators, both step-type and induction types, provide automatic voltage control for distribution circuits. These devices maintain constant voltage levels despite varying load conditions and source voltage fluctuations.

Monitoring and Control Infrastructure

SCADA and Communication Systems

Supervisory control and data acquisition (SCADA) systems allow remote monitoring and control of the substation equipment. More recent implementations use digital communication standards like IEC 61850, DNP3, and Modbus to integrate with utility control rooms.

Local data acquisition and control capabilities are provided by remote terminal units (RTUs) and intelligent electronic devices (IEDs). These devices transmit information about equipment status, measurements, and alarms to central control facilities and receive remote control signals.

Instrumentation and Metering

Revenue metering systems accurately measure energy consumption and demand for billing purposes. These precision instruments must meet strict accuracy requirements and provide tamper detection capabilities.

Power quality monitors track voltage, current, frequency, and harmonic distortion parameters. This data helps identify system problems and verify compliance with power quality standards.

Safety and Environmental Systems

Grounding and Lightning Protection

Substation grounding systems provide personnel safety and equipment protection by maintaining safe step and touch potentials. Ground grid design must consider soil conditions, fault current levels, and safety clearances.

Lightning protection systems, including surge arresters and overhead ground wires, protect equipment from atmospheric overvoltages. Proper coordination between protection devices ensures effective lightning performance while minimizing equipment stress.

Fire Protection and Environmental Controls

Fire detection and suppression systems protect valuable substation equipment from fire damage. These systems must be compatible with electrical equipment and provide rapid response to minimize damage.

Environmental monitoring systems track conditions such as temperature, humidity, and gas concentrations. This data helps optimize equipment performance and identify potential problems before they become critical.

Future Considerations and Technology Trends

The electrical power industry continues to evolve with advancing technology and changing grid requirements. Smart grid implementations demand enhanced communication capabilities and automated response systems. Energy storage integration requires new protection and control strategies.

Digital substation concepts promise improved reliability, reduced maintenance requirements, and enhanced operational flexibility. These implementations rely heavily on digital communication and advanced control algorithms.

Environmental considerations drive the development of more efficient and environmentally friendly electrical substation parts. This includes the phase-out of SF6 gas in favor of alternative insulating media and the implementation of more efficient transformer designs.

Conclusion

Electric substation components form a complex ecosystem of interconnected equipment that ensure reliable power delivery. From massive substation power transformers to sophisticated protection relay systems, each element contributes to the overall system performance and reliability. Realization of these components and interaction of these components is a very important point of the design, operation and maintenance of substations.

With the ongoing transformation in the electrical power industry, it is more important to keep abreast with the latest technology and the best practices in the industry. Integration of renewables, smart grids and energy storage systems poses new issues and opportunities in the design and operation of substations.

IET has more than 75 years of experience in electrical engineering solutions in the East Africa region specialising in Power Transmission and Distribution systems. Our complete experience in MV switchgear, transformers and intelligent control systems makes us the right partner to meet your next substation project. Call IET today to find out how our record of success and technical expertise can provide the reliable electrical infrastructure solutions your organization requires.

Leave a Reply