Manufacturing environment has transformed in a radical way in recent ten years, with the automated industrial solutions becoming the key component of excellence in work. Industries across East Africa now recognize that embracing automated industrial systems isn’t just an option—it’s a necessity for survival in an increasingly competitive global market.

This move towards automated industrial technology is not merely the flipping of a switch in installing a new equipment but the fundamental transformation on the way the facilities are run, how they maintain quality and how they bring value to their customers. The integration of automated industrial systems drives unprecedented levels of efficiency, reduces operational costs, and enables manufacturers to compete on a global stage while maintaining the flexibility to respond to rapidly changing market demands.

Understanding Automated Industrial Systems

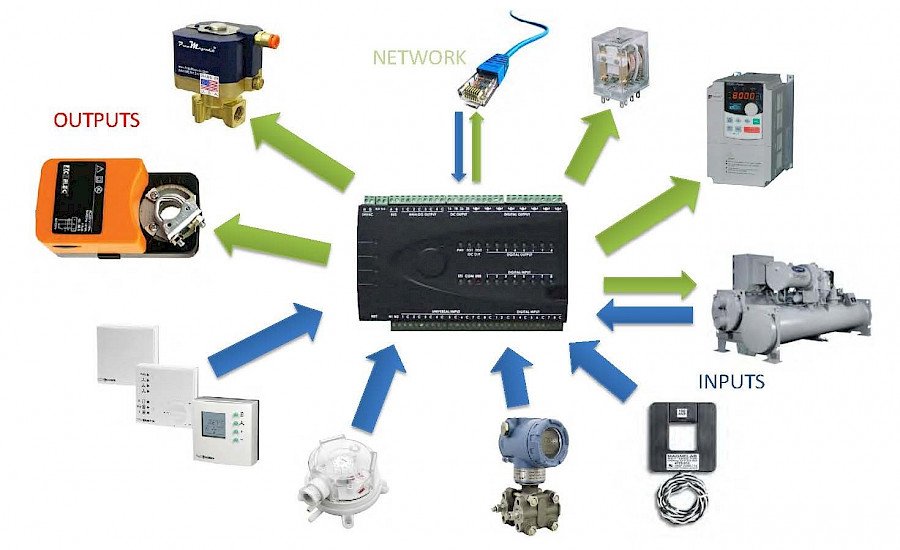

There are several elements that are essential to the harmony of automation of an industrial implementation. Programmable Logic Controllers (PLCs) provide the brains of the operation to analyze inputs of the sensors and to implement control logic with precision of milliseconds. Variable Frequency Drives (VFDs) have the property of controlled motor operation whereby acceleration, deceleration and speed are smooth and controlled to preserve equipment, and minimize energy use. The Human Machine Interfaces (HMIs) provide easy touchscreen interfaces through which operators monitor the processes, adjust the parameters and react to system alerts in real time.

Core Components of Automated Industrial Infrastructure

The foundation of any automated industrial implementation rests on several critical components working in harmony. PLCs are processors, which operate the control and take sensor inputs and run control logic with millisecond accuracy. Variable Frequency Drives (VFDs) offer a high level of control to the motor, providing the ability to accelerate, decelerate, and control the speed with smooth buffering, ensuring that equipment will not be damaged or damaged, and saving energy. Human Machine Interfaces (HMIs) develop inspiring surfaces on which operators track processes, make adjustments and react to system notifications in real-time.

Integration with Enterprise Systems

Modern automated industrial systems don’t operate in isolation—they integrate seamlessly with enterprise resource planning systems, manufacturing execution systems, and quality management platforms. Such integration forms a single data ecosystem through which production measurements flow directly to the business intelligence tools and the management is able to make efficient decisions using real time operational data. The connectivity inherent in automated industrial technology transforms raw sensor data into actionable insights that drive continuous improvement initiatives and strategic planning.

Scalability and Future-Proofing

One of the most compelling advantages of contemporary automated industrial solutions lies in their inherent scalability. Organizations can start with basic automation for critical processes and gradually expand their automated industrial systems as operational requirements evolve and budgets allow. This modular feature helps first investor to keep up with the trends in technology so that the money invested will not be wasted; furthermore, it will safeguard the capital investments earned without the loss of competitive advantage in the fast changing markets.

The Business Case for Automated Industrial Solutions

Investing in automated industrial infrastructure represents a strategic decision that delivers measurable returns across multiple dimensions of business performance. Manufacturing leaders who implement automated industrial systems consistently report improvements in productivity, quality, safety, and profitability that far exceed their initial investment projections. The financial justification for automated industrial technology becomes increasingly compelling as organizations calculate the total cost of ownership, including reduced labor costs, minimized waste, decreased downtime, and enhanced product consistency.

Productivity and Throughput Gains

Automated industrial solutions eliminate the bottlenecks and inconsistencies inherent in manual processes, enabling facilities to maintain optimal production rates around the clock. Unlike human operators who require breaks, shift changes, and ongoing training, automated industrial systems maintain consistent performance levels indefinitely. This level of reliability directly relates to a higher level of throughput with reports of productivity to increase by 30% to 200% depending on the types of applications and processes that are automated.

Quality Assurance and Consistency

Quality control represents another area where automated industrial technology delivers exceptional value. Automated vision systems are able to scan the products with high accuracy and consistency that cannot be matched with human inspectors, detect defects in the meters of a micron and at the same time, the automated systems can scan at the same speed as a high volume production line. The accuracy is a guarantee that only products that match the specifications perfectly reach the customers, minimizes any returns, warranty provisions, and any damage to reputation and creates brand loyalty due to constantly high-quality products.

Safety and Risk Mitigation

Implementing automated industrial systems removes personnel from hazardous environments, reducing workplace injuries and the associated costs of workers’ compensation, lost productivity, and regulatory compliance. The tasks performed by robots are very hazardous and include high temperature, harmful fumes, lifting heavy loads, and repetition which results in chronic injuries. This protective aspect of automated industrial solutions creates safer work environments while freeing skilled workers to focus on higher-value activities requiring human judgment and creativity.

Key Technologies Driving Automated Industrial Innovation

The rapid advancement of several enabling technologies has accelerated the adoption and capabilities of automated industrial solutions. Understanding these technologies helps organizations make informed decisions about which automated industrial systems best address their specific operational challenges and strategic objectives.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things connects sensors, actuators, and control systems into comprehensive networks that generate unprecedented visibility into operational performance. IIoT-enabled automated industrial technology collects and analyzes data from thousands of points across production facilities, identifying patterns, predicting failures, and optimizing processes in ways that were impossible just a few years ago. This connectivity transforms automated industrial systems from reactive tools into proactive platforms that anticipate and prevent problems before they impact production.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning algorithms bring adaptive intelligence to automated industrial environments. Through these technologies, systems are able to learn on the basis of historical data, to optimize processes without having to write programs and to automatically adapt to changing situations. Machine learning models embedded in automated industrial systems continuously improve their performance, identifying efficiency opportunities that human operators might never discover while maintaining the flexibility to respond to unexpected variations in materials, environmental conditions, or production requirements.

Edge Computing

Edge computing processes data locally within automated industrial installations rather than sending everything to remote cloud servers, dramatically reducing latency and enabling real-time responses to rapidly changing conditions. This distributed computing infrastructure guarantees that critical control procedures are detected within milliseconds and it maintains the reactivity needed by the high-speed manufacturing procedures and lowers bandwidth needs and improves information security because the sensitive operation data is on-premises.

Digital Twin Technology

Digital twins create virtual replicas of physical automated industrial systems, enabling organizations to simulate, test, and optimize processes without disrupting actual production. These digital models are used by engineers to test configuration setups, predict the need to maintain them and train drivers in riskless settings. This capability dramatically reduces the time and cost associated with implementing improvements to automated industrial technology while minimizing the risks of unintended consequences from process modifications.

Implementation Strategies for Automated Industrial Systems

Successfully deploying automated industrial solutions requires careful planning, stakeholder alignment, and systematic execution. Companies that are strategic in their automation rather than tactical have a high result with reduced risks and returns on investment.

Assessment and Prioritization

The first step in any automated industrial initiative involves comprehensively assessing current processes to identify automation opportunities. This assessment evaluates factors including production volumes, quality issues, safety concerns, labor availability, and strategic importance. Organizations then prioritize opportunities based on expected return on investment, implementation complexity, and strategic alignment. This systematic approach ensures that initial automated industrial systems implementations deliver maximum value while building organizational capabilities and confidence for subsequent phases.

Technology Selection

Choosing the right automated industrial technology requires balancing technical requirements, budget constraints, vendor capabilities, and long-term strategic considerations. Organizations must evaluate control platforms, communication protocols, sensor technologies, and integration approaches to ensure compatibility with existing infrastructure while maintaining flexibility for future expansion. Working with experienced automated industrial systems providers who understand regional conditions, support requirements, and industry-specific challenges significantly increases the likelihood of successful implementations.

Change Management

The human dimension of automated industrial transformations often presents greater challenges than technical implementation. Effective companies spend loads of money on change management, in which the employees are made to know how the automation will boost their job and not to eliminate them. Training programs that develop new skills, transparent communication about automation objectives, and inclusive processes that incorporate operator insights into system design all contribute to smooth transitions that capture the full potential of automated industrial investments.

Industry-Specific Applications of Automated Industrial Technology

Different industries leverage automated industrial systems in unique ways that address their specific operational challenges, regulatory requirements, and market dynamics.

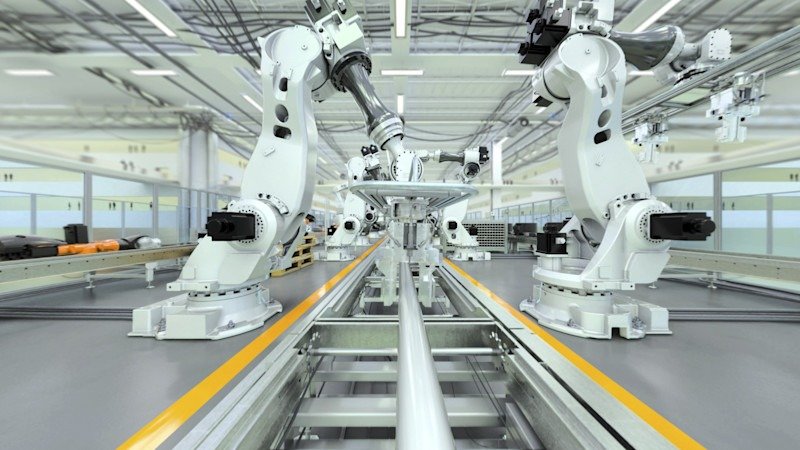

Manufacturing and Assembly

Manufacturing operations deploy automated industrial solutions across diverse applications including material handling, assembly operations, welding, painting, packaging, and palletizing. Robotic systems are precise and fast in tasks which are repetitive and are way beyond human capabilities and vision systems also provide quality at each production phase. Integration of these automated industrial systems with inventory management and production scheduling creates cohesive manufacturing environments where materials, information, and finished goods flow smoothly from raw materials to customer delivery.

Food and Beverage Processing

The food and beverage industry implements automated industrial technology to maintain strict hygiene standards, ensure consistent product quality, and manage complex regulatory compliance requirements. Automated cleaning-in-place systems, accurate dosing equipment and traceability solutions provide the production environment where safety and quality will not be left solely on the human vigilance. These automated industrial systems handle temperature-sensitive products, manage complex recipes, and document every aspect of production for regulatory audits and quality investigations.

Pharmaceutical Manufacturing

Automated material handling systems are used to prevent cross-contamination, electronic batch record systems used to remove documentation errors, and a system with serialization that is used to verify the authenticity of products in the global supply chain. The validation capabilities inherent in modern automated industrial systems simplify regulatory compliance while providing the detailed documentation required for inspections and audits.

Optimizing Energy Efficiency Through Automated Industrial Systems

Energy costs represent significant operational expenses for industrial facilities, making energy efficiency a critical consideration in automated industrial implementations. Modern automated industrial technology includes sophisticated energy management capabilities that reduce consumption while maintaining or improving production performance.

Intelligent Motor Control

Variable Frequency Drives form the cornerstone of energy-efficient automated industrial systems, adjusting motor speeds precisely to match load requirements rather than running continuously at full speed. This demand-based control reduces energy consumption by 20% to 50% in typical applications while extending motor life and reducing maintenance requirements. Advanced VFDs also provide power quality improvements, reducing harmonic distortion and protecting sensitive electronic equipment from electrical disturbances.

Load Monitoring and Optimization

Automated industrial platforms continuously monitor energy consumption across facilities, identifying equipment operating inefficiently, detecting abnormal consumption patterns that indicate maintenance requirements, and optimizing production schedules to leverage time-of-use electricity rates. Such visibility allows facilities managers to make decisions involving upgrades of equipment used, process improvements, and scheduling of operations in a way that minimizes the cost of energy and still achieves the production goals.

Predictive Maintenance

Predictive maintenance capabilities embedded in automated industrial systems use sensor data, vibration analysis, thermal imaging, and oil analysis to predict equipment failures before they occur. This preventive measure will avoid any unplanned downtime and will ensure the best utilisation of maintenance schedules using the real conditions of equipment instead of mere time intervals. Organizations implementing predictive maintenance through their automated industrial technology typically reduce maintenance costs by 25% to 30% while dramatically improving equipment availability and reliability.

The Role of Automated Industrial Systems Inc in Driving Innovation

Leading providers of automated industrial systems inc solutions continuously push the boundaries of what’s possible in industrial automation. Such organizations are heavy research and development and come up with innovative products that deal with new challenges without forfeiting backward compatibility in the existing installations. Partnership with established automated industrial systems inc providers gives organizations access to cutting-edge technology, proven implementation methodologies, and ongoing support that ensures long-term success.

Future Trends in Automated Industrial Technology

The evolution of automated industrial technology continues accelerating, with several emerging trends poised to reshape industrial automation over the coming years. Shopping these trends assists organizations to come up with strategic decisions concerning the investment in automation that is not becoming obsolete and outdated with the advent of technology.

Collaborative Robots

Collaborative robots, or cobots, represent a significant shift in automated industrial design philosophy. The cobots, unlike the old industrial robots that perform their duties in physical cages separated by human employees, are safe to work with human workers and they integrate human intelligence and flexibility in their robotic accuracy and stamina. This partnership sets up hybrid workplaces, in which organizations can leverage the human and robot workers to the fullest of their capabilities.

Augmented Reality

Augmented reality applications are transforming how technicians interact with automated industrial systems. AR glasses overlay digital information onto physical equipment, providing step-by-step maintenance instructions, highlighting components requiring attention, and enabling remote experts to guide on-site personnel through complex procedures. This technology reduces training requirements, accelerates troubleshooting, and ensures that best practices consistently guide maintenance and repair activities.

Advanced Analytics

Advanced analytics platforms transform the massive data streams generated by these systems into actionable intelligence. These platforms are based on statistical analysis, pattern recognition, and machine learning to find out the scope of improvement, anticipate quality problems, maximize process parameters, and cross-facility benchmarking of performance. Organizations leveraging advanced analytics from their automated industrial technology gain competitive advantages through insights that drive continuous improvement and operational excellence.

Partnering for Automated Industrial Success in East Africa

For over seven decades, IET has been at the forefront of electrical engineering excellence in East Africa, delivering comprehensive automated industrial solutions that transform manufacturing operations across Kenya, Uganda, and Tanzania. Our deep understanding of regional operating conditions, combined with partnerships with leading global technology providers, enables us to design, implement, and support automated industrial systems that deliver measurable results. We don’t just supply equipment—we become long-term partners in your automation journey, providing training, ongoing optimization, and responsive support that ensures your technology investments continue delivering value for years to come.

Ready to transform your operations with world-class automated industrial solutions? Contact IET today to discuss how our expertise in industrial automation, power systems, and control technologies can help you achieve your operational excellence goals. Visit our website at www.ietafrica.com or reach out to our team of experienced engineers who understand the unique challenges and opportunities facing East African manufacturers.