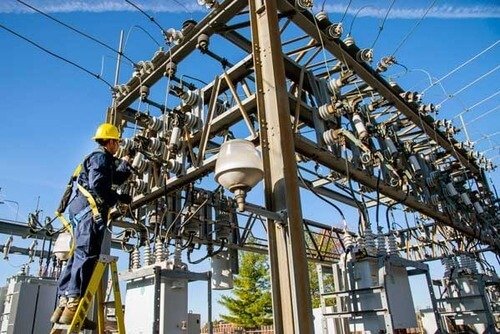

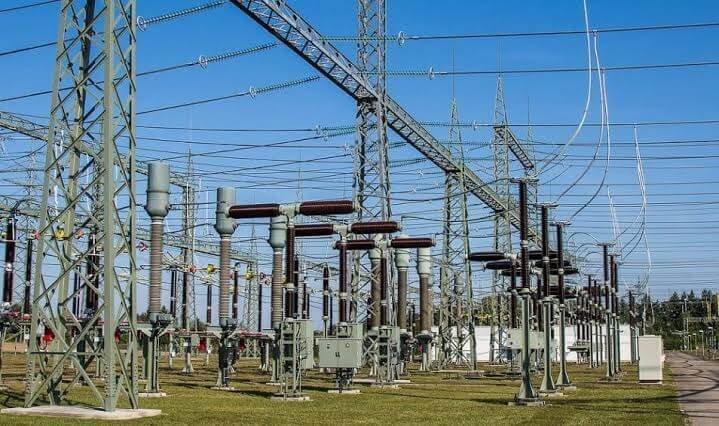

The backbone of any robust electrical power system lies in its substations, where the intricate art and science of substation design converge to create reliable, efficient power distribution networks. As power demands continue to escalate across industrial and commercial sectors, the importance of meticulously planned and executed substation projects cannot be overstated. Modern electrical substation design requires a deep understanding of both traditional engineering principles and cutting-edge technological innovations that drive today’s power infrastructure.

Electrical substations serve as critical nodes in power transmission and distribution networks, transforming voltage levels, switching circuits, and providing protection for downstream equipment. The complexity of these installations demands expertise that spans multiple engineering disciplines, from high-voltage equipment specification to sophisticated control system integration. Whether you’re dealing with transmission substations handling hundreds of kilovolts or distribution substations serving local communities, the fundamental principles of sound design remain paramount.

The evolution of substation technology has been remarkable over recent decades. Digital technologies, smart grid integration, and enhanced safety protocols have transformed how engineers approach substation projects. Today’s professionals must navigate increasingly complex regulatory environments while delivering solutions that meet stringent reliability requirements and environmental standards.

Fundamental Principles of Modern Substation Design

Understanding System Requirements and Load Analysis

Every successful substation project begins with comprehensive system analysis. Load forecasting forms the foundation of effective substation design, requiring engineers to analyze current demand patterns while projecting future growth scenarios. This analysis encompasses peak demand calculations, load diversity factors, and contingency planning for equipment failures or maintenance outages.

Power flow studies reveal how electrical energy moves through the proposed substation configuration under various operating conditions. These studies help determine optimal equipment ratings, identify potential bottlenecks, and validate the overall design approach. Short-circuit analysis ensures that protective equipment can safely interrupt fault currents, while stability studies confirm that the substation will maintain reliable operation during system disturbances.

The selection of voltage levels represents another critical design decision. Primary voltage levels must align with existing transmission and distribution infrastructure while providing adequate capacity for future expansion. Secondary voltage levels should match the requirements of connected loads or downstream distribution systems.

Equipment Selection and Specification

Modern substations incorporate sophisticated equipment that must work harmoniously within the overall system design. Power transformers represent the heart of most substations, requiring careful consideration of capacity, voltage ratios, cooling systems, and protection features. Transformer selection impacts numerous other design elements, from foundation requirements to fire protection systems.

Switchgear selection involves evaluating various technologies including air-insulated switchgear (AIS), gas-insulated switchgear (GIS), and hybrid solutions. Each technology offers distinct advantages depending on space constraints, environmental conditions, and operational requirements. GIS installations provide compact footprints ideal for urban applications, while AIS systems often prove more cost-effective for larger installations with adequate space.

Protection and control systems have evolved dramatically with digital technology integration. Modern protective relays offer extensive functionality beyond traditional overcurrent and differential protection, incorporating sophisticated monitoring, diagnostics, and communication capabilities that enhance overall system reliability.

Electrical Substation Layout Optimization and Spatial Planning

Site Selection and Preparation Considerations

Optimal site selection significantly influences both construction costs and long-term operational efficiency. Geotechnical investigations reveal soil conditions that affect foundation design and grounding system installation. Environmental assessments identify potential constraints related to wildlife protection, flood zones, or archaeological significance that may impact project development.

Access considerations encompass both construction logistics and long-term maintenance requirements. Equipment delivery routes must accommodate large transformers and other heavy components, while permanent access roads need to support maintenance vehicles and emergency response equipment. Strategic placement of maintenance facilities, spare parts storage, and administrative buildings contributes to operational efficiency.

Expansion planning requires allocating space for future equipment additions or upgrades. Many successful substations incorporate modular design approaches that facilitate systematic expansion as system requirements evolve. This forward-thinking approach minimizes future construction disruption while controlling long-term capital expenditure.

Clearance Requirements and Safety Zones

Electrical substation drawing specifications must incorporate minimum clearance requirements established by relevant standards and regulatory authorities. These clearances ensure safe operation and maintenance while preventing flashovers between energized components and grounded structures.

Live parts clearances vary with voltage levels and environmental conditions. Higher altitudes require increased clearances due to reduced air density, while coastal locations may need additional considerations for salt contamination. Working space requirements around equipment must accommodate maintenance personnel and specialized tools required for various operational tasks.

Fire protection zones influence equipment spacing and the placement of fire suppression systems. Oil-filled transformers require specific separation distances from buildings and other equipment, while fire walls may be necessary in space-constrained installations.

Rural and Remote Substation Design Challenges

Unique Considerations for Remote Installations

Rural substation design guide principles recognize the distinct challenges faced when developing power infrastructure in remote locations. Limited access to skilled labor, extended construction timelines, and challenging logistics significantly impact project planning and execution strategies.

Remote substations often require enhanced automation and monitoring capabilities to minimize the need for frequent site visits. SCADA systems and remote monitoring equipment enable operators to assess substation performance and respond to alarms from centralized control centers. This technology proves particularly valuable where travel to remote sites may be time-consuming or seasonally restricted.

Component redundancy becomes more critical in remote installations where equipment failures could result in extended outages due to repair logistics. Spare parts inventory management requires careful planning to balance carrying costs against the risk of extended downtime while awaiting replacement components.

Environmental and Climatic Adaptations

Remote substations frequently encounter harsh environmental conditions that influence equipment selection and installation practices. Temperature extremes, high humidity, dust, and wildlife interactions all impact long-term reliability and maintenance requirements.

Corrosion protection assumes greater importance in challenging environments. Protective coatings, cathodic protection systems, and material selection all contribute to extending equipment life in aggressive conditions. Regular inspection and maintenance programs must account for accelerated degradation in harsh environments.

Wildlife protection measures prevent animal-caused outages that can be particularly disruptive in remote areas. These measures include wildlife guards, nest deterrents, and specialized conductor designs that reduce the likelihood of animal contact with energized equipment.

Advanced Design Considerations and Modern Technologies

Digital Integration and Smart Grid Compatibility

Contemporary electrical substation design course curricula emphasize the integration of digital technologies that enable smart grid functionality. Advanced metering infrastructure, demand response capabilities, and distributed generation integration require substations equipped with sophisticated communication and control systems.

Cybersecurity considerations have become paramount as substations become increasingly connected to wider networks. Secure communication protocols, network segmentation, and regular security assessments help protect critical infrastructure from cyber threats while enabling beneficial connectivity features.

Data management systems capture and analyze vast quantities of operational data generated by modern substation equipment. This information supports predictive maintenance programs, performance optimization initiatives, and regulatory compliance reporting requirements.

Sustainability and Environmental Responsibility

Modern substation projects increasingly incorporate sustainability principles that minimize environmental impact throughout the facility lifecycle. Energy-efficient equipment selection, renewable energy integration capabilities, and end-of-life recycling considerations all contribute to environmental stewardship.

SF6 gas alternatives are gaining attention due to environmental concerns associated with traditional gas-insulated equipment. New insulation technologies offer comparable performance while reducing greenhouse gas emissions associated with substation operations.

Noise mitigation strategies address community concerns while maintaining operational requirements. Transformer noise reduction techniques, strategic equipment placement, and acoustic barriers help minimize the impact on surrounding areas.

Construction Excellence and Project Management

Substation Building Construction and Infrastructure Development

The physical infrastructure supporting substation operations requires careful coordination between multiple engineering disciplines. Control buildings must accommodate sophisticated equipment while providing comfortable working environments for operations personnel. These structures require specialized HVAC systems, fire suppression equipment, and security features appropriate for critical infrastructure applications.

Foundation systems must support heavy equipment loads while providing adequate grounding for electrical safety. Deep foundations may be required for large transformers, while specialized designs accommodate equipment with specific vibration isolation requirements. Proper drainage systems prevent water accumulation that could compromise electrical equipment or create safety hazards.

Cable systems and underground infrastructure require detailed coordination to avoid conflicts between different utilities and services. Cable routing must consider thermal effects, electromagnetic interference, and future maintenance requirements while providing adequate protection from environmental hazards.

Quality Assurance and Testing Protocols

Comprehensive testing programs validate substation performance before energization and throughout the operational lifecycle. Factory acceptance testing ensures that major equipment meets specified performance requirements before shipment. Site acceptance testing verifies proper installation and integration of all substation systems.

Commissioning procedures systematically verify that all substation systems operate correctly under various conditions. These procedures typically progress from individual component testing to integrated system validation, ensuring that protective systems, communication networks, and control systems function as designed.

Ongoing maintenance and testing programs maintain reliable operation throughout the substation lifecycle. Predictive maintenance techniques, including dissolved gas analysis for transformers and infrared thermography for electrical connections, help identify potential problems before they result in equipment failures.

Conclusion

The field of substation design continues evolving as new technologies emerge and power system requirements become increasingly sophisticated. Success in this domain requires mastering both fundamental engineering principles and staying current with technological innovations that shape modern power infrastructure. From initial system studies through long-term operational support, every aspect of substation development demands attention to detail and commitment to excellence.

Effective substation construction projects result from collaborative efforts between experienced engineers, skilled construction teams, and knowledgeable operations personnel. The integration of digital technologies, sustainability considerations, and enhanced safety protocols creates opportunities for improved performance while presenting new challenges that require innovative solutions.

As East Africa’s power infrastructure continues expanding to meet growing industrial and commercial demands, the importance of expert substation design and construction services becomes increasingly apparent. IET brings over 75 years of regional experience to complex substation projects, combining deep technical expertise with practical knowledge of local conditions and requirements. Our comprehensive approach encompasses everything from initial feasibility studies through long-term maintenance support, ensuring that your critical power infrastructure investments deliver reliable performance for decades to come. Contact IET today to discover how our proven substation design capabilities can support your next power infrastructure project.

Leave a Reply