The industrial landscape has undergone a remarkable transformation over the past few decades, with electrical automation serving as the cornerstone of this evolution. What began as simple mechanical processes has evolved into sophisticated, interconnected systems that respond intelligently to operational demands. This technological revolution has fundamentally changed how industries approach efficiency, safety, and productivity.

Modern facilities no longer rely on manual oversight and mechanical controls. Instead, they leverage automated electrical systems that can predict, adapt, and optimize performance in real-time. The integration of advanced sensors, programmable logic controllers, and intelligent software has created an ecosystem where human intervention becomes strategic rather than operational.

The shift toward comprehensive automation electrical solutions represents more than just technological advancement—it embodies a fundamental reimagining of industrial operations. Organizations that embrace these technologies find themselves better positioned to compete in an increasingly demanding global marketplace.

Understanding the Core Components of Modern Electrical Automation

Intelligent Control Systems

At the heart of every effective electrical automation system lies a sophisticated control architecture. These systems integrate multiple layers of intelligence, from basic input/output processing to advanced algorithmic decision-making. Modern programmable logic controllers (PLCs) serve as the central nervous system, processing thousands of data points per second while maintaining precise control over critical operations.

The evolution from simple relay-based controls to microprocessor-driven systems has enabled unprecedented levels of precision and reliability. Today’s controllers can handle complex mathematical calculations, implement advanced control algorithms, and communicate seamlessly with enterprise-level systems. This integration allows for holistic operational visibility and control.

Variable frequency drives (VFDs) exemplify how individual components contribute to system-wide efficiency. These devices not only control motor speed and torque but also provide detailed feedback on performance metrics, energy consumption, and predictive maintenance indicators. The data generated becomes invaluable for optimizing overall system performance.

Sensor Networks and Data Acquisition

The proliferation of intelligent sensors has transformed how electrical automation controls gather and process information. Modern sensor networks extend far beyond traditional temperature and pressure monitoring, incorporating vibration analysis, power quality assessment, and even environmental factors that might impact operations.

Advanced data acquisition systems create comprehensive operational profiles that enable predictive analytics and proactive maintenance strategies. These systems can identify patterns that precede equipment failures, allowing maintenance teams to address issues before they impact production. The integration of wireless sensor networks has further expanded monitoring capabilities while reducing installation complexity.

Real-time data processing capabilities ensure that automation electrical systems can respond immediately to changing conditions. This responsiveness is crucial in applications where even minor deviations can result in significant operational or safety consequences.

Strategic Implementation Approaches

System Architecture Design

Successful implementation of electrical automation requires careful consideration of system architecture from the outset. The design phase must account for current operational requirements while building in flexibility for future expansion and technological evolution. This forward-thinking approach prevents costly retrofits and ensures long-term system viability.

Network topology plays a crucial role in determining system reliability and performance. Modern industrial networks utilize redundant communication paths and failover mechanisms to ensure continuous operation even when individual components experience issues. The selection of communication protocols directly impacts system interoperability and future expansion possibilities.

Integration with existing infrastructure presents both challenges and opportunities. Experienced electrical automation engineers understand how to leverage legacy systems while introducing new technologies that enhance overall capabilities. This hybrid approach often provides the most cost-effective path to modernization.

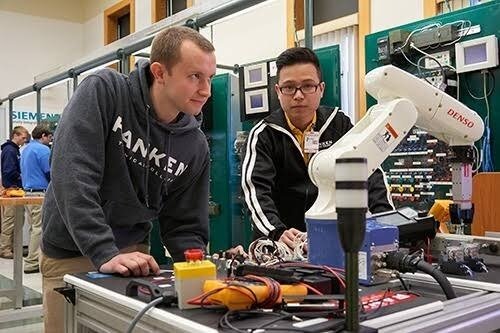

Human-Machine Interface Evolution

The relationship between operators and automated electrical systems has evolved significantly as interfaces become more intuitive and informative. Modern human-machine interfaces (HMIs) provide comprehensive operational visibility while simplifying complex processes into manageable, actionable information.

Touchscreen displays have largely replaced traditional button and switch panels, offering dynamic interfaces that can adapt to different operational modes and user preferences. These systems provide real-time graphics, trend analysis, and alarm management that enable operators to make informed decisions quickly.

Mobile accessibility has become increasingly important as operational teams require remote monitoring and control capabilities. Modern systems provide secure access through mobile applications and web-based interfaces, allowing key personnel to maintain operational awareness regardless of location.

Industry-Specific Applications and Benefits

Manufacturing and Process Industries

Manufacturing environments have embraced electrical automation services to achieve levels of precision and consistency that manual operations simply cannot match. Automated production lines can maintain tolerances measured in microns while operating continuously for extended periods. This capability directly translates to improved product quality and reduced waste.

Process industries, including chemical, pharmaceutical, and food processing, rely on electrical engineering and automation to maintain strict environmental controls and ensure product safety. Automated systems can maintain precise temperature, pressure, and chemical composition parameters while documenting every aspect of the production process for regulatory compliance.

The integration of quality control systems with production automation creates closed-loop processes that can automatically adjust parameters based on real-time quality measurements. This approach minimizes defects and reduces the need for costly post-production corrections.

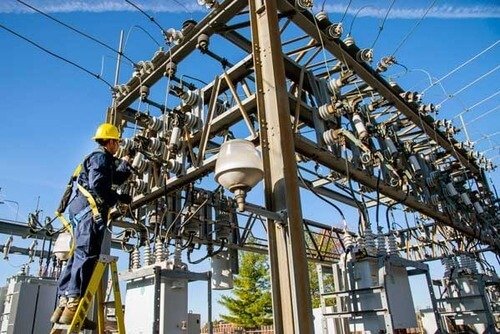

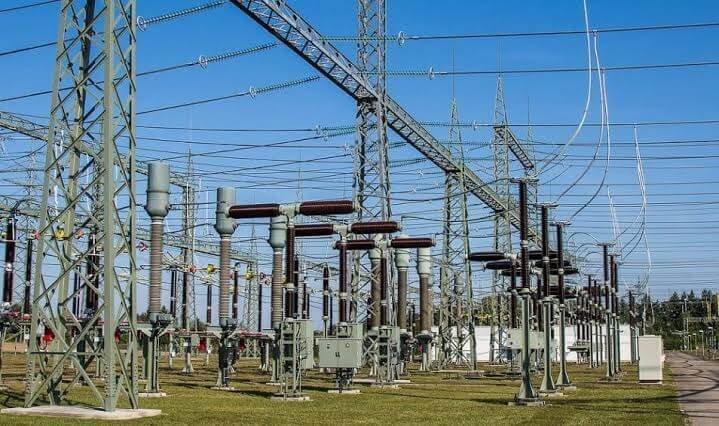

Infrastructure and Utilities

Power generation and distribution systems represent some of the most sophisticated applications of electrical automation technology. These systems must maintain stable operations while accommodating variable demand and integrating renewable energy sources. Advanced control systems can automatically balance generation and consumption while optimizing efficiency across the entire grid.

Water treatment and distribution facilities utilize automated systems to maintain water quality standards while minimizing energy consumption. These systems can adjust treatment processes based on source water quality variations and optimize pump operations based on demand patterns.

Building automation systems integrate HVAC, lighting, and security systems to create environments that automatically adapt to occupancy patterns and environmental conditions. These systems can significantly reduce energy consumption while maintaining optimal comfort levels.

Advanced Technologies Shaping the Future

Artificial Intelligence Integration

The incorporation of artificial intelligence into electrical automation systems represents the next evolutionary step in industrial control. Machine learning algorithms can analyze vast amounts of operational data to identify optimization opportunities that might not be apparent through traditional analysis methods.

Predictive analytics capabilities enable systems to forecast equipment failures, optimize maintenance schedules, and adjust operational parameters based on predicted demand patterns. This proactive approach significantly reduces unplanned downtime while optimizing resource utilization.

Neural networks can learn from historical operational data to create models that improve system response to various operational scenarios. These adaptive systems become more effective over time, continuously refining their performance based on actual operational experience.

Edge Computing and Real-Time Processing

Edge computing has emerged as a critical component in modern electrical automation controls by bringing processing power closer to the point of operation. This approach reduces latency and ensures that critical control functions remain operational even if communication with central systems is interrupted.

Distributed processing architectures enable complex calculations to be performed locally while maintaining coordination with enterprise-level systems. This balance between local autonomy and centralized coordination provides both operational reliability and strategic visibility.

Real-time analytics at the edge enable immediate response to changing conditions while simultaneously providing data to higher-level systems for strategic analysis. This multi-tiered approach ensures both operational effectiveness and strategic insight.

Cybersecurity and System Protection

As automated electrical systems become more connected and sophisticated, cybersecurity has become a paramount concern. Modern automation systems must incorporate multiple layers of security to protect against both external threats and internal vulnerabilities.

Network segmentation and secure communication protocols ensure that critical control systems remain isolated from potential attack vectors while maintaining necessary connectivity for operational purposes. Regular security updates and monitoring systems help maintain protection against evolving threats.

Access control and authentication systems ensure that only authorized personnel can modify system parameters or access sensitive operational data. These systems maintain detailed logs of all system interactions for security analysis and regulatory compliance.

Measuring Success and Continuous Improvement

Performance Metrics and Key Indicators

Successful implementation of electrical automation requires comprehensive measurement systems that track both operational and financial performance. Key performance indicators should include energy efficiency, production throughput, quality metrics, and equipment reliability measures.

Energy consumption analysis provides immediate feedback on system optimization effectiveness. Modern monitoring systems can identify energy waste at the component level, enabling targeted improvements that deliver measurable results.

Overall equipment effectiveness (OEE) metrics provide a comprehensive view of how automation improvements impact productivity. These measurements account for availability, performance, and quality factors to provide a holistic assessment of operational improvement.

Return on Investment Analysis

The financial benefits of electrical automation services extend beyond simple labor cost reductions. Comprehensive ROI analysis should account for energy savings, improved product quality, reduced maintenance costs, and enhanced operational flexibility.

Payback periods for automation investments have decreased significantly as technology costs have declined and capabilities have expanded. Many organizations realize positive returns within 18-24 months of implementation, with benefits continuing to accrue throughout the system lifecycle.

Long-term value creation through automation includes improved competitiveness, enhanced safety performance, and increased operational resilience. These strategic benefits often exceed the direct financial returns from efficiency improvements.

The Path Forward

The future of industrial operations lies in the continued evolution and integration of electrical automation technologies. Organizations that embrace these technologies while maintaining focus on strategic objectives will find themselves well-positioned for long-term success.

Successful automation implementation requires partnership with experienced providers who understand both the technical aspects of modern systems and the strategic requirements of industrial operations. The complexity of modern electrical automation systems demands expertise that spans multiple technical disciplines while maintaining focus on operational excellence.

For over seven decades, IET has been at the forefront of electrical engineering innovation across East Africa. Our comprehensive expertise in power transmission, industrial automation, and building management solutions positions us as the ideal partner for organizations seeking to leverage the full potential of electrical automation. With operations spanning Kenya, Uganda, and Tanzania, we understand the unique challenges and opportunities in our region. Contact IET today to discover how our proven electrical automation solutions can transform your operations and deliver measurable results.