Modern buildings are complex ecosystems with thousands of systems working simultaneously to maintain comfort, safety, and efficiency. BMS technology is the backbone of these intelligent operations. These systems transform how facilities manage everything, including HVAC systems and lighting controls.

Understanding what does BMS stand for and how these systems function is essential. With the increased complexity of commercial and industrial facilities, the application of a robust building management solution directly affects the cost of operation and energy use and the satisfaction of occupants.

BMS technology represents more than just automation—it delivers comprehensive oversight of building operations through integrated digital platforms. The market of intelligent solutions is growing rapidly across the world. In East Africa, particularly Kenya, Uganda, and Tanzania, the increase in energy price and sustainability requirements are contributing to this growth.

Organizations that master this technology implementation gain competitive advantages through reduced operational expenses and enhanced facility performance. This guide discusses the inherent principles, elements and strategic deliberations that characterize building management systems in the contemporary world.

Understanding BMS: Definitions and Core Concepts

The abbreviation of BMS refers to Building Management System, though some professionals interchange this with Building Automation System (BAS). What do BMS stand for extends beyond the acronym itself. These systems represent integrated platforms that monitor and control mechanical, electrical, and electromechanical services throughout buildings.The BMS abbreviation has become the standard in the industry with some differences across the regions. The term BMS makes them inquire about what is the full name of the control systems when they inquire of professionals BMS what does it stand.

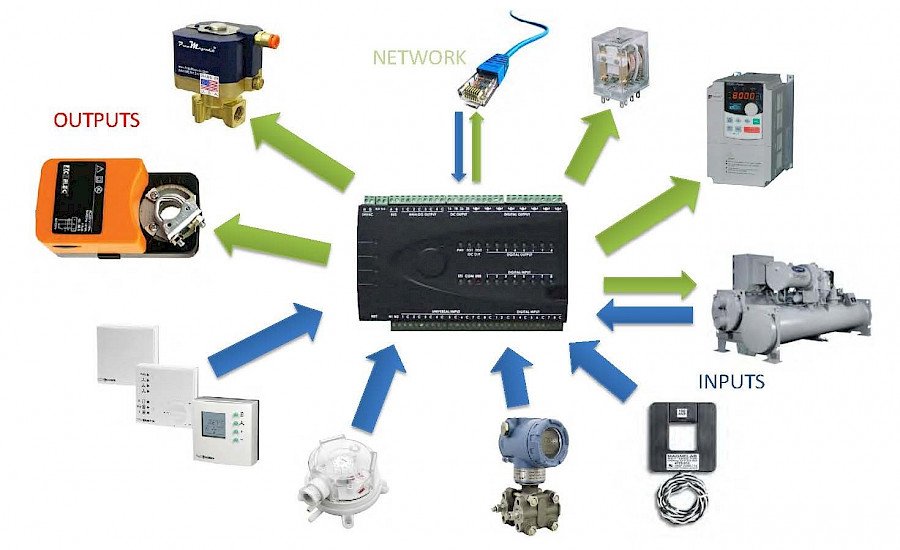

Whats BMS mean in practical terms involves centralized computer-based control of building systems including heating, ventilation, air conditioning, lighting, power systems, fire safety, and security. The controller BMS serves as the brain of the operation, processing data from thousands of sensors and executing control sequences based on programmed logic.

Whats does BMS stand for encompasses both the hardware components—sensors, actuators, and controllers—and the software platforms that enable system integration and user interaction. Modern BMS technology has evolved from simple thermostatic controls to sophisticated AI-enabled platforms that learn occupancy patterns and optimize operations automatically.

Key Components of BMS Technology

Field Controllers and Sensors

The foundation of any BMS technology implementation begins with field-level devices. Controller BMS units function as distributed intelligence throughout the building, processing local data and executing control commands. These controllers are either small application-specific controllers that control single air handling units, all the way to large programmable logic controllers (PLCs) that control a complete system. Temperature sensors, humidity detectors, pressure transducers, and occupancy sensors continuously feed data to controller BMS units, creating real-time awareness of building conditions.

Modern sensors offer wireless connectivity and enhanced accuracy. The BMS technology ecosystem relies on these devices to provide accurate environmental data that drives decision-making algorithms. Flow meters monitor water and steam consumption while power meters track electrical usage at granular levels. All the sensors are part of the total data environment that facilitates smart building management. Installation quality directly affects sensor performance, making professional commissioning essential for reliable BMS technology deployment.

Communication Networks and Protocols

BMS technology depends on robust communication infrastructure connecting thousands of devices throughout facilities. Such standard protocols as BACnet, Modbus, and LonWorks allow the equipment of various manufacturers to communicate freely. The controller BMS architecture typically employs hierarchical networks, with high-speed Ethernet backbone connections linking floor-level controllers to central servers. Understanding communication protocols proves critical when specifying BMS technology solutions, as protocol selection affects system flexibility and future expandability.

Network reliability determines BMS technology effectiveness—redundant pathways and proper network segmentation prevent single points of failure. Current implementation is employing more of IP-based implementation, and it builds on the existing infrastructure in information technology but ensures the security of its use with proper VLAN design. Hardwired connections are used to supplement wireless technologies in retrofit designs where installation of cables is difficult. The communication layer represents the nervous system of BMS technology, transmitting control signals and data across the facility infrastructure.

Operator Interfaces and Analytics Platforms

User interaction with BMS technology occurs through sophisticated graphical interfaces displaying real-time system status. Modern operator workstations introduce animated floor plans, trending charts and notification of alarm, which allow management of the facility effectively. The software tier will convert raw sensor data into insights incorporating an action plan, including anomalies and suggestions of operation changes. Mobile applications extend BMS technology access beyond control rooms, allowing facility staff to monitor conditions and adjust setpoints remotely.

Analytics capabilities distinguish advanced BMS technology implementations from basic automation systems. Machine learning algorithms determine patterns in the performance of buildings by forecasting equipment failures even before they happen. Energy dashboards are visualizations of the consumption trends in order to allow the facility managers to see areas of optimization. Reporting tools produce regulatory documentation and measures of performance that meet the regulatory needs. The interface layer determines how effectively building operators leverage BMS technology capabilities in daily operations.

Strategic Benefits of BMS Technology Implementation

Energy Efficiency and Cost Reduction

Organizations implementing BMS technology typically achieve energy savings between 15-30% through optimized equipment scheduling and demand-based operation. The controller BMS continuously adjusts HVAC output based on actual occupancy rather than fixed schedules, eliminating wasted conditioning of unoccupied spaces. Advanced control programs avoid heating and cooling as the buildings of such sophistication are prone to inefficiency when they are manually controlled. Load shedding capabilities integrated into BMS technology reduce peak demand charges by strategically timing equipment operation.

BMS technology enables facility managers to implement sophisticated energy conservation measures like optimal start/stop scheduling, night setback strategies, and enthalpy-based economizer control. Real time monitoring also detects equipment that is not working in line with the design, corrective measures can be taken before its efficiency is severely affected. Utility cost allocation becomes straightforward when BMS technology includes comprehensive submetering capabilities. The financial justification for this technology investment often rests primarily on energy savings, with payback periods typically ranging from two to five years depending on facility complexity and baseline efficiency.

Enhanced Occupant Comfort and Productivity

BMS technology directly influences workplace satisfaction by maintaining consistent environmental conditions throughout facilities. The controller BMS responds rapidly to changing conditions, adjusting ventilation rates and temperature setpoints to maintain comfort. Sophisticated zoning strategies enabled by BMS technology allow different areas to maintain varied conditions suited to their specific functions. During the occupancy of conference rooms, more ventilation is applied whilst storage areas are minimally conditioned during blank intervals.

Studies consistently demonstrate that occupant comfort and productivity improve in buildings equipped with advanced BMS technology. Lighting integration design develops the right intensity of lights and minimizes waste of energy. The quality of air monitoring will provide the facility managers with notification of the ventilation deficiencies prior to the complaints of the occupants. The capability of modifying zone conditions in individuals is a solution to the different comfort seekings in buildings. When occupants feel comfortable in their environment, productivity increases and absenteeism decreases—benefits that far exceed the direct energy savings from BMS technology implementation.

Predictive Maintenance and Equipment Longevity

BMS technology revolutionizes maintenance strategies by shifting from reactive repairs to predictive interventions. The controller BMS continuously monitors equipment runtime, start counts, and performance metrics that indicate impending failures. Attaching temperature sensors to rotating equipment will give information on the early malfunction of the lubrication. Dealing with the decreasing trend of efficiency causes proactive filter replacement and coil inings before comfort complaints have been raised. This anticipatory power shortens the cost of repairing the equipment in case of emergency and prolongs the life of the equipment.

Maintenance management integration capabilities within BMS technology platforms automatically generate work orders based on runtime schedules and performance thresholds. History equipment that follows up on equipment maintenance keeps a record of all maintenance operations, which helps in passing warranty, as well as replacement decisions. The comprehensive data logging inherent in this technology enables sophisticated reliability analysis, identifying problematic equipment models and informing future procurement decisions. The cost savings in facilities that take advantage of such capabilities are usually 25-40% in reference to cost-reduction of reactive maintenance strategies.

Implementation Considerations for BMS Technology

System Design and Specification

Successful BMS technology projects begin with comprehensive facility assessment and clear stakeholder requirements. The design phase defines controller BMS architecture, network topology, and interface requirements that align with operational needs. Excessive capacity of the system enables expansion in the future but undersizing imposes restrictions now. Specification documents must clearly define communication protocols, ensuring equipment compatibility across manufacturers. Performance requirements should address response times, data logging intervals, and alarm management capabilities.

BMS technology specifications should mandate open protocols avoiding proprietary systems that create vendor lock-in. Integration requirements need detailed documentation covering existing systems that must interface with new BMS technology implementations. Specification phase defines the success of a project- vague requirements give rise to commissioning conflicts and function disappointments. Engaging experienced consultants during design ensures BMS technology solutions appropriately match facility complexity and organizational capabilities.

Installation and Commissioning

BMS technology installation quality directly affects long-term system reliability and performance. Good sensor location is done according to the suggestions of the manufacturer whilst bearing in mind the air movement and interference by the occupants. Controller BMS mounting locations require environmental protection from temperature extremes and moisture exposure. Installation of the network infrastructure should be of a standard that satisfies the data transmission requirements that are well terminated and labeled. The professional teams of installations are aware of the finesse of what constitutes a satisfactory installation or a remarkable one.

Commissioning represents the critical phase where BMS technology transforms from installed equipment into functional control systems. Functional testing validates that controller BMS units execute programmed sequences correctly under various operating conditions. Calibration of sensors is used to obtain an accurate measure on which control decisions are based. Commissioning also involves operator training whereby the facility staff is acquainted with the capabilities of the system and how they can run it on a daily basis. Inadequate commissioning undermines even the best BMS technology designs, leading to systems that never achieve their performance potential.

Training and Change Management

BMS technology adoption requires organizational change beyond technical installation. Training of the full set of operators creates the competencies required to take advantage of the capabilities of systems. Facility staff must understand controller BMS programming logic, alarm response procedures, and interface navigation. Advanced training covers optimization strategies and troubleshooting methodologies that maximize BMS technology value. Continuous training is a solution to staff turnover and systems upgrades during the facility lifecycle.

Change management deals with the change in culture that comes with BMS technology adoption. Conventional facilities were based on mechanical prowess whereas the new BMS technology requires the use of IT literacy and ability to interpret data. Employee opposition to change can be mitigated once the employees realize that BMS technology eases their day to day duties as opposed to jeopardizing their jobs. It is important to create specific guidelines regarding the changes made to the system to ensure that the changes made cannot be changed by an unauthorized person to affect the performance. Organizations with the correct training and change management achieve by far higher returns on the BMS technology investments.

Future Trends in BMS Technology

The development of BMS technologies does not stop there, as the artificial intelligence development provides the possibility of controlling buildings autonomously. Cloud-based platform of technology BMS makes remote monitoring and management possible through distributed facility portfolios. The proliferation of IoT sensors creates new volumes of data never seen before that advanced analytics changes into operational intelligence. Cybersecurity is becoming a more critical concern due to the technology of BMS being linked to larger IT networks. The controller BMS of tomorrow will leverage edge computing capabilities processing data locally while coordinating with cloud-based optimization engines.

BMS technology is becoming more and more interconnected with enterprise systems, putting energy information into carbon accounting systems and maintenance information into asset management systems. A possible solution in offering secure and transparent energy trade in microgrids under the management of BMS technology is found in blockchain technology. The possibilities of digital twin allow trying control strategies in simulation and implementing them in reality. The merging of BMS technology and smart grids places buildings as active energy markets participants and not passively consume energy.

Conclusion

BMS technology has developed rapidly due to its luxury applications growing to be vital infrastructure of a contemporary commercial and industrial facility. Understanding what BMS stands for and how these systems function empowers organizations to optimize building performance, reduce operational costs, and enhance occupant satisfaction. The controller BMS serves as the intelligent foundation managing increasingly complex building systems through integrated digital platforms. BMS technology has strategic implementation which yields quantifiable gains in energy efficiency, maintenance optimization and operational excellence. With increasing complexities and sustainability requirements becoming stipulated, the strength of the building management system shifts its competitive edge to a need to operate.

IET Africa incorporates 75 years of electrical engineering expertise to all projects in Kenya, Uganda, and Tanzania through the provision of expert BMS technology solutions to organizations. Our Building Management Solutions integrate the best industry components with local technical experience to get the best performance of the system with the entire lifecycle of your facility. Our team provides turnkey solutions of BMS technology, including all the design, consultation and installation, and commissioning up to the maintenance of the technology so as to ensure that your facility is efficient and reliable. Contact IET Africa today to discover how our proven building automation expertise can transform your facility operations and deliver measurable results for your organization.