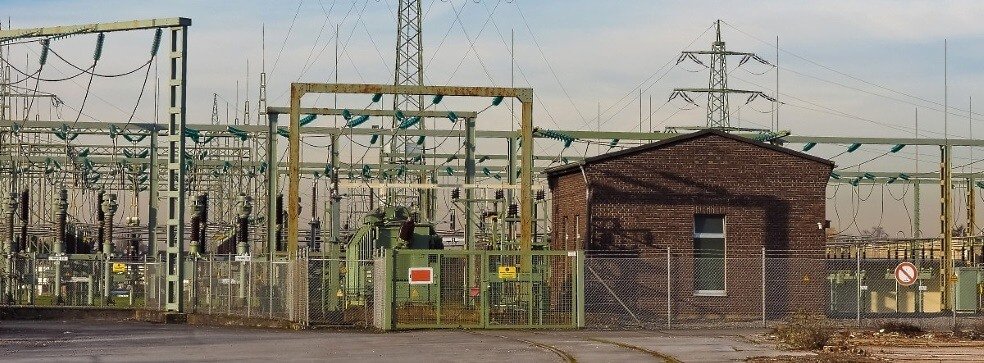

The design and construction of electrical substations is critical to the performance of any electrical power system. Electrical substations components are the nerve centers for transforming, distributing, and controlling electrical power flow across networks. This makes electrical substation building a necessity that demands technical and strategic foresight.

The present-day power grids are struggling to keep up with new challenges, with the demand to integrate more renewable energy, and the necessity to ensure a greater resilience of the grids. The nature of the electrical infrastructure in the modern environment is very complex and demanding a profound knowledge of the technical specifications is not sufficient to take the design to its operational stage as the complex interdependence of different parts of the sub-systems, environmental factors to be considered, and the long term functional needs have to be understood well.

To an experienced electrical engineer, the art of developing substations goes much beyond installation of equipment. It involves a thorough site study, complex protection strategies, state-of-the-art automation and a combination of latest technologies that will deliver power reliably in the next decades.

Essential Components of Modern Substation Infrastructure

Power Transformation Equipment

Transformation capabilities are the heart of any substation. The load characteristics, fault tolerance, and thermal management of high-voltage transformers are places where special attention should be paid as it is the main linkage between transmission and distribution systems. Step-down transformers will require selecting not only based on current demand but also future growth trends so that the infrastructure will remain viable over the lifespan of their operation.

The latest transformer installations have built-in modern monitoring systems displaying the real-time information about temperature, oil quality, and internal conditions. These smart systems provide the possibility of predictive maintenance approaches that greatly prolong the life of equipment, and minimize surprise breakdowns.

Switchgear and Protection Systems

Medium voltage switchgear forms the protective backbone of substation operations. Circuit breakers, disconnect switches, and protective relays work in concert to isolate faults and maintain system stability. The selection of switchgear technology—whether air-insulated (AIS) or gas-insulated (GIS)—depends heavily on space constraints, environmental conditions, and reliability requirements.

Protection schemes have evolved from simple overcurrent devices to sophisticated digital relay systems capable of advanced fault analysis and communication with other protective devices across the network. These systems incorporate features like:

- Differential protection for transformers and bus sections

- Distance protection for transmission lines

- Frequency and voltage regulation capabilities

- Communication protocols for SCADA integration

- Cybersecurity measures for digital protection systems

Design Considerations for Optimal Performance

Site Selection and Environmental Factors

The foundation of successful electrical substation building begins with comprehensive site evaluation. Soil conditions directly impact grounding system effectiveness, requiring detailed resistivity measurements and geological assessments. Factors such as seismic activity, flood zones, and extreme weather patterns must be incorporated into structural design specifications.

Elevation considerations affect both equipment selection and protection requirements. High-altitude installations may require derating of equipment or enhanced insulation coordination due to reduced air density. Similarly, coastal installations demand special attention to corrosion protection and salt contamination mitigation.

Electrical Design Parameters

Load flow studies and short-circuit analysis form the technical foundation for substation design. These studies determine conductor sizing, protection device ratings, and fault current capabilities throughout the system. Proper coordination studies ensure that protective devices operate in the correct sequence during fault conditions, minimizing system disruptions.

Grounding system design represents one of the most critical safety aspects of substation construction. The ground grid must provide low-resistance fault paths while maintaining safe step and touch potentials during fault conditions. Computer modeling helps optimize grid design to meet safety standards while minimizing material costs.

Construction Methodologies and Best Practices

Project Planning and Execution

Electrical substation construction firms tend to adopt a phased nature of the project delivery wherein initial stages are the detailed engineering and procurement activities followed by the construction activities. Modern substations are very complex and therefore the work of various professions such as civil, electrical, protection and telecommunications engineering, have to be coordinated.

The use of the modular type of construction has become popular due to the benefits of speed of on-site construction and quality control. Factory-built control buildings, pre-assembled switchgear modules and tested protection panels are some of the items that can make a big difference in the schedule of a project with little compromise in quality.

Quality Assurance and Testing

Comprehensive testing protocols ensure that all substation components function correctly both individually and as integrated systems. Factory acceptance tests (FAT) verify equipment performance before shipment, while site acceptance tests (SAT) confirm proper installation and commissioning.

Testing procedures encompass:

- Primary injection testing of protection systems

- Insulation resistance and dielectric strength verification

- Control circuit continuity and logic verification

- Communication system functionality testing

- SCADA system integration validation

Integration of Advanced Technologies

Automation and Control Systems

Modern substations incorporate sophisticated SCADA systems that provide remote monitoring and control capabilities. These systems enable operators to respond quickly to changing system conditions while maintaining detailed historical records for analysis and maintenance planning.

Digital substations represent the cutting edge of substation technology, utilizing IEC 61850 communication protocols to create fully integrated automation systems. Process buses and merging units replace traditional copper wiring with fiber optic communication links, reducing installation complexity while enhancing system reliability and flexibility.

Smart Grid Integration

The evolution toward smart grid technologies has transformed substation requirements. Advanced metering infrastructure (AMI) integration, demand response capabilities, and renewable energy interconnection all require sophisticated control and communication systems.

Energy storage integration at the substation level provides grid stabilization services and peak shaving capabilities. Battery energy storage systems (BESS) require specialized protection schemes and fire suppression systems, adding complexity to traditional substation designs.

Specialized Considerations for Different Applications

Transmission Substations

High-voltage transmission substations require specialized design considerations for insulation coordination and clearance requirements. Air-insulated substations demand significant land area but offer accessibility advantages for maintenance activities. Gas-insulated substations provide compact solutions for urban environments but require specialized maintenance procedures and SF6 gas handling protocols.

Distribution Substations

Distribution-level installations focus on serving local load requirements with emphasis on reliability and cost-effectiveness. Automatic voltage regulators, capacitor banks for power factor correction, and load tap changers help maintain power quality while optimizing system efficiency.

Distribution automation systems enable remote switching and fault isolation, reducing outage duration and improving customer satisfaction. These systems integrate with advanced distribution management systems (ADMS) to provide operators with comprehensive system visibility.

Regulatory Compliance and Safety Standards

International Standards Adherence

Electrical substation contractors must navigate complex regulatory environments that vary by region and application. International standards such as IEEE, IEC, and local regulatory requirements establish minimum safety and performance criteria that must be incorporated into all design and construction activities.

Environmental regulations increasingly impact substation design, particularly regarding SF6 gas handling, oil containment, and noise emission limits. Proper documentation and compliance verification are essential throughout the project lifecycle.

Safety Management Systems

Comprehensive safety programs protect both construction personnel and operational staff throughout the substation lifecycle. Electrical safety procedures, confined space protocols, and emergency response plans must be developed and implemented for each project.

Arc flash analysis determines appropriate personal protective equipment (PPE) requirements and safe work procedures for maintenance activities. Regular updates to arc flash studies ensure that safety protocols remain current as system configurations change.

Maintenance and Asset Management Strategies

Predictive Maintenance Technologies

Condition-based maintenance strategies utilize advanced monitoring technologies to optimize maintenance schedules and prevent unexpected failures. Thermal imaging, partial discharge monitoring, and oil analysis provide early warning of potential problems, allowing for proactive maintenance intervention.

Digital twins and asset management software platforms integrate maintenance data with operational information to support optimal decision-making regarding equipment replacement and system upgrades.

Lifecycle Cost Optimization

Electrical substation installation decisions significantly impact long-term operational costs. Initial equipment selection must balance capital costs against maintenance requirements, energy efficiency, and expected service life. Total cost of ownership analysis helps optimize these competing factors to achieve maximum value over the asset lifecycle.

Future Trends and Emerging Technologies

The electrical power industry continues to evolve rapidly, driven by renewable energy integration, digitalization, and changing load patterns. Microgrids and distributed energy resources require substations to accommodate bidirectional power flows and dynamic operating conditions.

Artificial intelligence and machine learning technologies promise to revolutionize substation operations through predictive analytics and autonomous control systems. These technologies will enable more efficient asset utilization while maintaining the high reliability standards expected from critical infrastructure.

Conclusion

The discipline of electrical substation building represents a critical intersection of engineering excellence, technological innovation, and strategic infrastructure planning. Technical competence is not the only requirement necessary to succeed in this field as one needs to be familiar with changing requirements in the industry and upcoming technology.

With power systems growing more complex, as well as more interconnected, the skills needed to complete successful substation projects are growing in number as well. During initial feasibility studies, commissioning and continued operation there are phases that require specialized knowledge and caution.

IET has served as the first choice electrical engineering partner in East Africa to major projects related to complex substation construction projects in Kenya, Uganda and Tanzania over 7 decades. A combination of in-depth knowledge of power transmission and distribution and insight into the infrastructure needs of the region makes us the right fit to support your next critical power infrastructure project. Call IET now to learn how our history of success can help make your substation development projects a success.

Leave a Reply