The manufacturing landscape has undergone a profound transformation over the past decade, with automation industrial systems emerging as the cornerstone of modern production excellence. Today’s industrial facilities demand more than traditional mechanization; they require intelligent, interconnected systems that can adapt, optimize, and respond to changing market conditions in real-time. This evolution represents not just a technological upgrade but a fundamental shift in how we conceptualize manufacturing efficiency, quality control, and competitive advantage in an increasingly digital world.

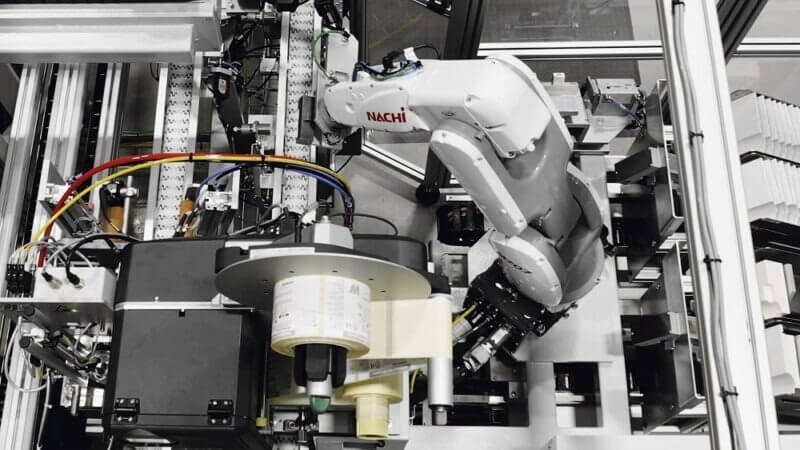

Automation industrial technologies have moved far beyond simple programmable logic controllers and basic sensor networks. Modern systems integrate artificial intelligence, machine learning algorithms, and advanced analytics to create self-optimizing production environments that continuously improve performance. These sophisticated platforms enable manufacturers to achieve unprecedented levels of precision, consistency, and operational efficiency while reducing waste, minimizing downtime, and enhancing worker safety across all production processes.

The strategic implementation of these systems requires deep understanding of both technological capabilities and operational requirements. Successful integration demands careful consideration of existing infrastructure, workforce capabilities, and long-term business objectives. Furthermore, the rapid pace of technological advancement means that today’s automation solutions must be designed with future scalability and adaptability in mind, ensuring that investments remain valuable as industry standards continue to evolve.

Foundations of Modern Industrial Automation Engineering

Core Technologies and System Architecture

Industrial automation engineering has evolved into a highly sophisticated discipline that combines electrical engineering principles with advanced computer science and data analytics. Modern automation systems rely on distributed control architectures that can manage complex processes across multiple production lines simultaneously. These systems typically incorporate programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) platforms working in harmony to create seamless operational control.

The integration of Internet of Things (IoT) sensors and edge computing devices has revolutionized data collection and processing capabilities within industrial environments. These devices capture real-time information about equipment performance, environmental conditions, and product quality, transmitting this data to centralized control systems for analysis and decision-making. Advanced communication protocols such as Ethernet/IP, Profinet, and OPC-UA ensure reliable, high-speed data exchange between disparate system components.

Cybersecurity considerations have become paramount in modern industrial automation engineering projects. As systems become more connected and data-driven, protecting critical infrastructure from cyber threats requires implementing robust security measures at every level of the automation hierarchy. This includes secure communication protocols, encrypted data transmission, access control systems, and regular security audits to maintain system integrity and protect proprietary manufacturing processes.

Integration Challenges and Solutions

The complexity of modern manufacturing operations presents unique challenges for automation system integration. Legacy equipment often operates on outdated communication protocols or proprietary systems that resist easy integration with newer technologies. Successful projects require careful planning to bridge these gaps while maintaining operational continuity throughout the implementation process. This often involves developing custom interfaces, protocol converters, and middleware solutions that enable seamless communication between old and new systems.

Workforce adaptation represents another critical aspect of successful automation implementation. While these systems are designed to enhance human capabilities rather than replace workers entirely, they do require new skill sets and operational procedures. Training programs must address not only technical operation but also troubleshooting, maintenance, and optimization techniques that enable workers to maximize system performance. Additionally, change management strategies help organizations navigate the cultural adjustments that accompany technological transformation.

Scalability planning ensures that initial automation investments can grow with business needs over time. Modular system architectures allow for incremental expansion of automation capabilities without requiring complete system redesigns. This approach enables organizations to implement automation in phases, spreading costs over time while demonstrating value at each stage of implementation. Furthermore, standardized component selection and documentation practices facilitate future modifications and upgrades.

Advanced Industrial Automation Technology Applications

Manufacturing Process Optimization

Industrial automation technology applications in manufacturing process optimization have transformed how companies approach quality control, efficiency improvement, and cost reduction. Advanced process control systems use mathematical models and real-time feedback to automatically adjust operating parameters, maintaining optimal conditions even as raw material properties or environmental factors change. These systems can detect minute variations in product quality and make instantaneous corrections that would be impossible for human operators to achieve.

Predictive maintenance capabilities represent one of the most valuable applications of modern automation technology. By continuously monitoring equipment vibration, temperature, pressure, and other key parameters, these systems can predict component failures before they occur. This proactive approach dramatically reduces unplanned downtime, extends equipment life, and optimizes maintenance scheduling. Machine learning algorithms analyze historical data patterns to improve prediction accuracy over time, creating increasingly reliable maintenance forecasts.

Quality assurance processes have been revolutionized through the integration of vision systems, precision measurement tools, and automated testing equipment. These technologies can inspect products at speeds far exceeding human capabilities while maintaining consistent accuracy standards. Automated quality control systems can detect defects, measure dimensions, verify assembly completeness, and perform functional testing with minimal human intervention. When integrated with production control systems, they can automatically adjust process parameters to prevent future quality issues.

Energy Management and Sustainability

Modern industrial process automation systems play a crucial role in achieving sustainability goals and optimizing energy consumption across manufacturing operations. Intelligent energy management systems monitor power usage patterns, identify inefficiencies, and automatically implement energy-saving measures during low-production periods. These systems can coordinate equipment startup and shutdown sequences to minimize peak demand charges while maintaining production schedules.

Advanced motor control systems, particularly variable frequency drives (VFDs), offer significant energy savings by matching motor speed to actual load requirements rather than running at constant speeds. When integrated with automation systems, these drives can respond to real-time production demands, reducing energy consumption by 20-50% in many applications. Smart motor control centers can also provide detailed energy usage analytics that help identify additional optimization opportunities.

Waste reduction initiatives benefit tremendously from automation technology implementation. Precise material handling systems minimize spillage and contamination while ensuring optimal material utilization. Automated inventory management systems track material consumption in real-time, enabling just-in-time delivery strategies that reduce storage requirements and material waste. Additionally, closed-loop control systems can automatically recycle process streams, recovering valuable materials that would otherwise be discarded.

Data Analytics and Performance Monitoring

The convergence of automation systems with big data analytics has created unprecedented opportunities for manufacturing intelligence and continuous improvement. Modern industrial automation platforms generate massive amounts of operational data that, when properly analyzed, reveal insights into process optimization, equipment performance, and quality improvement opportunities. Advanced analytics platforms can identify correlations between seemingly unrelated variables, enabling operators to understand root causes of performance variations.

Real-time dashboards and reporting systems provide management with instant visibility into key performance indicators across all production areas. These systems can track metrics such as overall equipment effectiveness (OEE), energy consumption, quality rates, and production throughput, presenting information in formats that facilitate quick decision-making. Alert systems automatically notify relevant personnel when parameters exceed acceptable ranges, enabling rapid response to potential issues.

Historical data analysis capabilities enable long-term trend analysis and strategic planning support. By examining production data over extended periods, manufacturers can identify seasonal patterns, equipment degradation trends, and process drift that might not be apparent in day-to-day operations. This information supports capital planning decisions, maintenance scheduling, and process improvement initiatives that drive long-term competitive advantage.

Implementation Strategies and Best Practices

Project Planning and System Design

Successful industrial automation technology implementations require comprehensive planning that addresses both technical and organizational factors. The initial assessment phase should include detailed analysis of existing processes, identification of automation opportunities, and establishment of clear performance objectives. This assessment forms the foundation for system design decisions and helps ensure that automation investments align with business goals and operational requirements.

System architecture design must balance performance requirements with budget constraints while maintaining flexibility for future expansion. Standardization of components, communication protocols, and programming practices reduces long-term maintenance costs and simplifies troubleshooting procedures. Additionally, modular design approaches enable phased implementation strategies that spread costs over time while minimizing operational disruption during installation periods.

Risk assessment and mitigation planning are essential components of any automation project. Potential failure modes must be identified and addressed through redundant systems, backup procedures, and emergency shutdown capabilities. Cybersecurity risks require particular attention, with security measures integrated into system design from the beginning rather than added as an afterthought. Regular security audits and updates ensure that protection measures remain effective against evolving threats.

Integration and Commissioning

The integration phase of automation industrial projects requires careful coordination between multiple engineering disciplines and vendor representatives. Mechanical, electrical, and software components must work together seamlessly, requiring extensive testing and validation procedures. Factory acceptance testing (FAT) allows for system validation before installation, reducing on-site commissioning time and minimizing production disruption.

Commissioning procedures should include comprehensive testing of all system functions under simulated operating conditions. This includes normal operation testing, emergency shutdown procedures, and failure mode analysis to ensure that systems respond appropriately under all circumstances. Documentation of all test procedures and results provides valuable reference material for future troubleshooting and modification activities.

Training delivery during the commissioning phase ensures that operations and maintenance personnel are prepared to assume responsibility for system operation. Hands-on training with actual equipment is far more effective than classroom instruction alone, enabling personnel to develop confidence and competence with new systems. Additionally, vendor support during the initial operating period helps resolve unexpected issues and optimize system performance.

Performance Optimization and Continuous Improvement

Post-implementation optimization represents an ongoing opportunity to maximize the value of automation investments. Performance monitoring systems should track key metrics and identify opportunities for further improvement. Regular analysis of operational data can reveal optimization opportunities that weren’t apparent during initial system design. This data-driven approach to continuous improvement ensures that automation systems continue to deliver value long after initial installation.

Maintenance procedures must evolve to support the increased complexity of automated systems. Preventive maintenance programs should address not only mechanical components but also software updates, calibration procedures, and cybersecurity measures. Predictive maintenance capabilities enable transition from time-based to condition-based maintenance strategies, reducing maintenance costs while improving equipment reliability.

User feedback collection and analysis help identify system improvements and training needs that emerge during normal operations. Regular review meetings with operations personnel can reveal usability issues, feature requests, and process improvements that enhance system effectiveness. This feedback loop ensures that automation systems continue to meet evolving operational needs and user expectations.

Future Trends and Technological Developments

Artificial Intelligence and Machine Learning Integration

The integration of artificial intelligence and machine learning capabilities into industrial process automation systems represents the next frontier in manufacturing intelligence. These technologies enable systems to learn from operational data and automatically optimize performance without human intervention. Advanced algorithms can identify subtle patterns in process data that human operators might miss, leading to improved efficiency, quality, and reliability across all manufacturing operations.

Machine learning applications in predictive maintenance are becoming increasingly sophisticated, with algorithms capable of analyzing multiple data streams simultaneously to predict equipment failures with remarkable accuracy. These systems can learn from both successful operations and failure modes, continuously improving their predictive capabilities. Furthermore, artificial intelligence can optimize maintenance scheduling by considering production requirements, parts availability, and resource constraints simultaneously.

Quality control applications of machine learning technology can detect defective products with accuracy levels that exceed traditional inspection methods. Vision systems enhanced with deep learning algorithms can identify subtle defects, classify problems by type and severity, and automatically adjust process parameters to prevent future occurrences. These capabilities are particularly valuable in industries where product quality is critical and inspection costs are high.

Edge Computing and Real-Time Analytics

Edge computing technologies are transforming how industrial automation engineering approaches data processing and decision-making. By processing data locally at the point of collection, edge computing systems can make real-time decisions without relying on cloud connectivity. This approach reduces latency, improves system reliability, and enables autonomous operation even when communication networks are disrupted.

Real-time analytics capabilities at the edge enable immediate response to changing conditions without waiting for data to travel to centralized processing systems. This is particularly valuable for safety-critical applications where rapid response is essential. Edge computing platforms can also filter and pre-process data before transmitting to higher-level systems, reducing bandwidth requirements and improving overall system performance.

The combination of edge computing with 5G connectivity promises to enable new applications that require ultra-low latency and high reliability. Mobile robots, autonomous vehicles, and remote control applications can benefit from these technologies, expanding the possibilities for flexible manufacturing systems. Additionally, edge computing enables distributed intelligence that can continue operating even when individual components or communication links fail.

Sustainable Manufacturing and Circular Economy

Automation industrial systems are increasingly designed to support sustainable manufacturing practices and circular economy principles. Advanced process control systems can optimize resource utilization, minimize waste generation, and maximize energy efficiency across all manufacturing operations. These capabilities are becoming essential as companies face increasing pressure to reduce environmental impact while maintaining competitiveness.

Circular economy applications of automation technology include systems that automatically sort and process waste streams for recycling or reuse. Vision systems can identify different materials and direct them to appropriate processing equipment, while process control systems optimize recovery rates and product quality. These applications not only reduce environmental impact but also create new revenue streams from previously discarded materials.

Carbon footprint tracking and optimization capabilities are being integrated into manufacturing execution systems, enabling real-time monitoring of environmental impact. These systems can automatically adjust operations to minimize carbon emissions while maintaining production targets. Additionally, integration with renewable energy systems allows manufacturing facilities to optimize energy consumption based on renewable energy availability and grid conditions.

Conclusion

The evolution of automation industrial systems continues to reshape manufacturing excellence, driving unprecedented improvements in efficiency, quality, and sustainability across diverse industrial sectors. Modern industrial automation technology platforms offer capabilities that were unimaginable just a few years ago, enabling manufacturers to achieve new levels of operational excellence while preparing for an increasingly competitive and environmentally conscious marketplace.

The strategic implementation of these technologies requires careful planning, skilled execution, and ongoing optimization to maximize return on investment. Organizations that embrace comprehensive automation strategies position themselves to capitalize on emerging opportunities while building resilience against market uncertainties. Furthermore, the integration of artificial intelligence, machine learning, and advanced analytics capabilities promises to unlock even greater value from existing automation investments.

Success in today’s competitive manufacturing environment demands more than just implementing the latest technology; it requires deep expertise in industrial process automation design, integration, and optimization. The complexity of modern systems means that partnering with experienced automation specialists is essential for achieving optimal results while minimizing implementation risks and ensuring long-term system reliability.

For over 75 years, IET has been East Africa’s premier electrical engineering company, delivering sophisticated automation industrial solutions across Kenya, Uganda, and Tanzania. Our comprehensive expertise in industrial automation drives, motor control centers, building management solutions, and system integration makes us the ideal partner for organizations seeking to transform their manufacturing operations. Contact IET today to discover how our proven automation solutions and deep regional expertise can drive your manufacturing excellence and competitive advantage.

Leave a Reply